As industries strive toward sustainability, the role of vibration isolation often goes overlooked. However, minimizing vibrations isn’t just about equipment longevity or precision—it’s about energy efficiency, reduced waste, and creating a more sustainable future.

When it comes to cutting-edge vibration isolation, air springs are in a league of their own. These advanced systems offer unparalleled performance for industries that demand precision and adaptability, from semiconductor manufacturing to heavy industrial machinery.

As technology evolves, industries are relying on increasingly sophisticated and sensitive equipment. Whether it’s semiconductor manufacturing or pharmaceutical research, even the slightest vibration can disrupt processes, compromise precision, and lead to costly errors. This is why vibration isolation has become a cornerstone for modern high-tech industries.

As technology evolves, industries are relying on increasingly sophisticated and sensitive equipment. Whether it’s semiconductor manufacturing or pharmaceutical research, even the slightest vibration can disrupt processes, compromise precision, and lead to costly errors. This is why vibration isolation has become a cornerstone for modern high-tech industries.

As technology evolves, industries are relying on increasingly sophisticated and sensitive equipment. Whether it’s semiconductor manufacturing or pharmaceutical research, even the slightest vibration can disrupt processes, compromise precision, and lead to costly errors. This is why vibration isolation has become a cornerstone for modern high-tech industries.

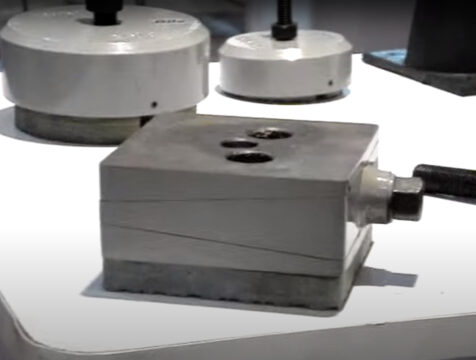

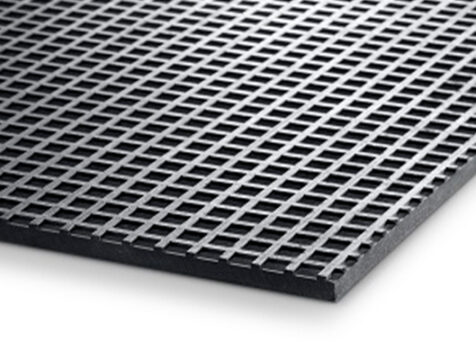

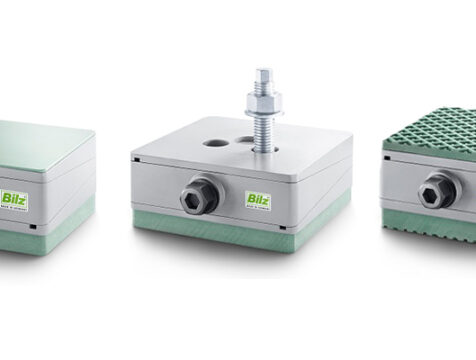

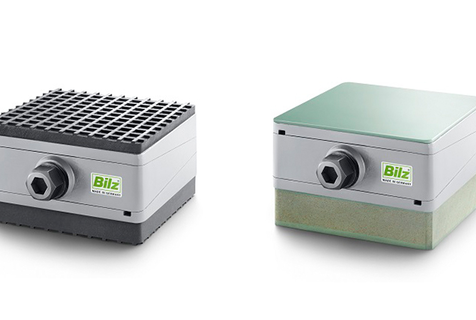

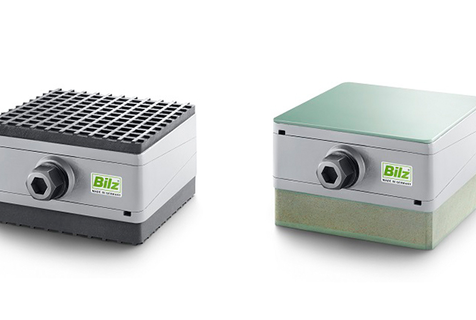

When it comes to industrial machinery, the smallest vibrations can have the biggest consequences. Whether it’s affecting precision in manufacturing or disrupting sensitive equipment in labs, the need for a stable foundation is critical. This is where Bilz isolation pads come into play.

In today’s fast-paced industrial world, precision is paramount. Whether in manufacturing, research, or construction, unwanted vibrations can severely impact the accuracy, safety, and longevity of equipment. That’s where vibration isolation technology steps in as a game-changer, offering solutions that enhance performance across industries.

In today’s fast-paced industrial world, precision is paramount. Whether in manufacturing, research, or construction, unwanted vibrations can severely impact the accuracy, safety, and longevity of equipment. That’s where vibration isolation technology steps in as a game-changer, offering solutions that enhance performance across industries.

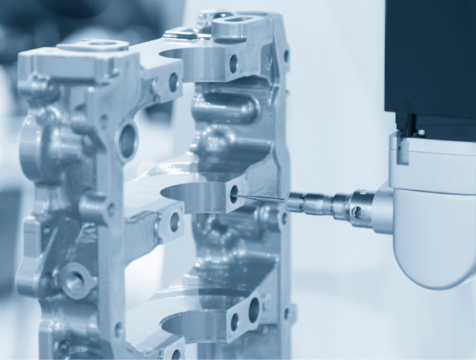

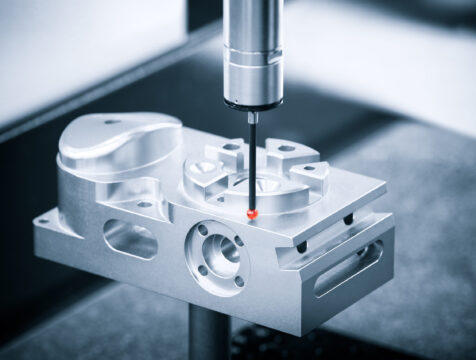

In industries where precision is paramount, such as manufacturing quality control and research laboratories, achieving accurate measurements is critical for ensuring product quality and scientific validity. This blog explores the significant impact of advanced vibration isolation systems offered by Bilz Vibration Technology in enhancing measurement accuracy and operational efficiency.

IMTS 2024 in Chicago brought together industry leaders, innovators, and customers from around the world to showcase the latest advancements in manufacturing technology. One standout highlight of the event was Zygo’s cutting-edge optical profiling technology, presented by Michael Schmid, Senior Product Development Manager for Zygo’s optical profiler team. During the event, Schmid introduced Zygo’s flagship […]

MTS 2024 at Chicago’s McCormick Place was an unforgettable experience for Bilz USA! As the premier event for the manufacturing industry, IMTS provides an incredible platform for showcasing innovations, connecting with industry leaders, and learning about the latest trends in technology. Marc Brower, owner and chief engineer at Bilz USA, shared his thoughts on the […]

For Original Equipment Manufacturers (OEMs), the commitment to using the highest quality machine leveling and vibration isolation technologies is a strategic investment in their product’s future.

For OEM design engineers, the early integration of machine leveling and vibration isolation into product design is not just a best practice—it’s a cornerstone of excellence in engineering.

In the aerospace and defense industry, the margin for error is virtually nonexistent. The precision manufacturing and rigorous testing of components and systems for aircraft, satellites, and defense equipment require the utmost in accuracy and stability.

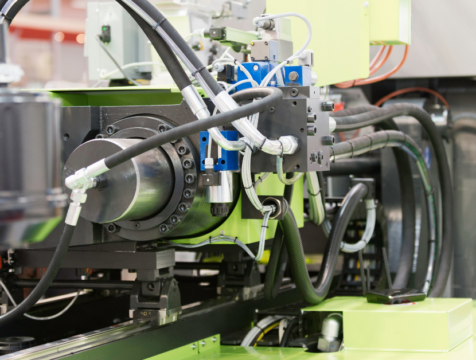

Granular Damping in Machine Bases: Discuss the use of granular damping materials within machine bases for injection molding and extrusion machines. This technique involves embedding granular materials that, under vibration, reconfigure to absorb energy and dampen oscillations, thereby stabilizing the machine.

In the rapidly evolving plastics and polymers industry, precision and stability in manufacturing processes are more than operational goals—they are critical requirements.

In the automotive industry, precision manufacturing is not just a goal; it’s a requirement. The integration of machine leveling and anti-vibration technologies plays a pivotal role in meeting the stringent standards of quality and efficiency demanded by the sector.

Kinematic Couplings: Detail how kinematic couplings are used to achieve precise, repeatable positioning in robotic bases, ensuring that the robotic arm or platform returns to the same position after movement or load changes.

In the rapidly evolving field of robotics, precision and stability are paramount. The integration of machine leveling and anti-vibration technologies plays a critical role in enhancing the performance and longevity of robotic systems.

As the manufacturing sector moves further into the digital age, the integration of digital technologies and automation in machine leveling processes represents a significant leap forward.

Following our exploration of the fundamentals of machine leveling in manufacturing, it’s clear that precision leveling is paramount for optimizing machinery performance and product quality.

Machine leveling is a critical procedure in the manufacturing of components and parts, ensuring precision, stability, and optimal performance of machinery. The right leveling solutions not only enhance the operational efficiency of equipment but also significantly extend its lifespan.

A leading manufacturer of large diesel engines was experiencing significant issues with their surface finish measurements. The problem arose during the use of a bar surface finish gauge to measure critical engine components, such as the inside of the piston bore.

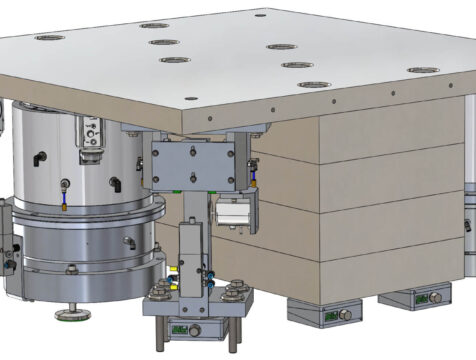

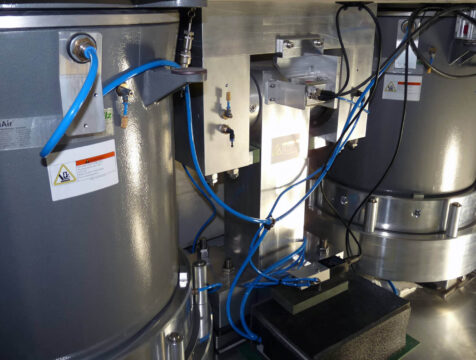

In the realm of vibration isolation, achieving optimal performance and reliability is critical for various industrial applications. Bilz’s Active Isolation System (AIS) High Performance Binnig Rohner stands out as a premier solution, offering unparalleled advantages over other systems. Let’s delve into why the Bilz AIS High Performance Binnig Rohner surpasses its competitors.

Question: Dear Marc, I’m interested in your pad sets. Do you make them 100 mm square? Is there a cost sheet per type and quantity? I am familiar with some of your small precision position systems. Are you also making larger motion control stages? Answer: Thank you for reaching out with your questions about our […]

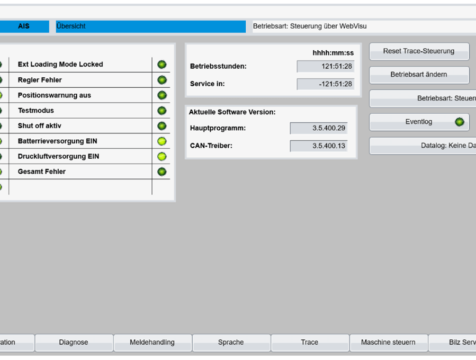

In today’s fast-paced industrial environment, the need for precise and efficient control systems is more critical than ever. Bilz is proud to introduce groundbreaking advancements in our EPN, EPPC, and AIS systems that redefine performance, reliability, and affordability. Our latest innovations leverage state-of-the-art technology to deliver superior control and unprecedented convenience, setting a new standard […]

Question: Dear Marc, How do I go about getting a vibration site survey? I’m getting vibration on my surface finish gauge. The vibration is coming from our honing machine. I’ve tried using anti-vibration mats to no avail. I’d like to get a survey and recommendation on how to isolate the gauge. Answer: Vibration issues in […]

Our recent technical training journey in Germany, hosted by our parent company, was packed with insights, valuable experiences, and the latest developments in electronic systems. As the distributor overseeing the U.S. territory, this trip was an invaluable opportunity to deepen our understanding of the products, strategies, and technological advancements essential for our market.

Question: Dear Marc, Have you had any issues with the pads wearing through or cracking after 15 years? Our machine is 60 tons with cyclical vibrations running 24/7. We would like to mount it on wedge shoes like you provide, but we have concerns about the pads wearing through and requiring full disassembly, leading to […]

Question: Dear Marc, I’m interested in the PKA 80. What is the life cycle of this shoe and the vibration pad? We want to ensure that the pad will not wear faster than the machine’s life. It is a 60-ton machine with large amounts of vibrations. Answer: I do not have a defined lifetime for […]

Bilginoğlu: laboratory benches for optimal vibration isolation Laboratory table at Bilginoğlu Endustri Malzemeleri Bilginoğlu Endustri Malzemeleri 9 standard sizes

One of our proven solutions for machine mounting: vibration-isolated platforms Modular platform with optimised centre of gravity for AIS High Performance Machines and installations > 35 t

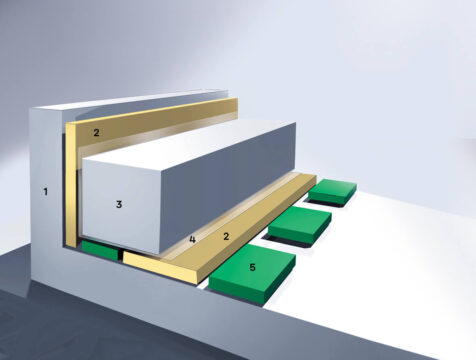

Our solution for an automotive plant: foundation insulation with isolation pad sets and lost formwork 1 Foundation tray (side wall), 2 Mineral fibre and cover panels (lost formwork), 3 Foundation block, 4 PVC foil cover, 5 Bilz insulation panels (set of panels), 6 Foundation trough (base) Foundation block 1.200 t

Reliable source isolation of a 23-ton punching machine with FAEBI® rubber air springs with foundation insulation Foundation block approx. 5.1 x 3.5 x 1.0 m, weight approx. 40 t. Foundation block 40 t

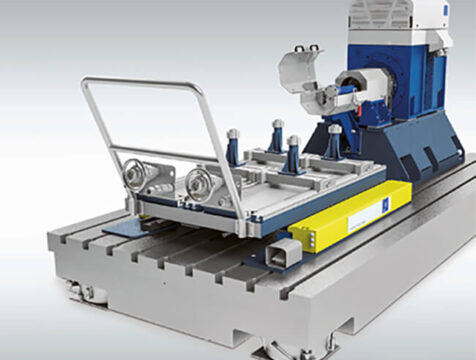

Successful receiver isolation of a gear grinding machine with BiAir® membrane air springs and oscillating foundation Gear grinding machine GLEASON PFAUTER P 1200 G, machine weight incl. tool up to 25 t, foundation block approx. 5.2 x 1.9 x 0.7 m, approx. 20 t Foundation block 25 t

BD Rowa™: customised solution for automatic order pickers BD Rowa™ gripper – Image source: BD Rowa™ BD Rowa™ Very high damping ration up to 30% Use at – 20°C up to + 80°C

Hexagon Manufacturing Intelligence: our wide range of solutions for ultra-high accuracy measuring instruments The Leitz Infinity is the most accurate 3D coordinate measuring machine (CMM) in its class and also enables the combination of optical and tactile sensors in a highly accurate measuring system. Hexagon Manufacturing Intelligence Reproducibility of measuring results in the micrometre area […]

Buja Metaal: convincing source insulation for a 500 to press Hursan press with use of FAEBI® rubber air springs for Buja Metaal Buja Metaal Isolation efficiency ratio > 90 %

Our first blog post aims to inform and inspire readers about the potential of advanced materials in enhancing vibration isolation solutions. If you find this approach suitable. Advanced Materials in Vibration Isolation: Explore the cutting-edge materials being developed and used in vibration isolation, such as metamaterials, smart polymers, and nano-engineered composites. Review how these materials […]

Introduction: The field of vibration isolation is ever-evolving, with continuous innovations and research shaping the future of how we manage and mitigate vibrations across various industries. Workshops and seminars offer invaluable platforms for professionals to share knowledge, discuss challenges, and showcase the latest technological advancements. This blog post consolidates key takeaways from recent workshops and […]

Introduction: In the world of vibration isolation, the primary goal is often to prevent unwanted movement that can disrupt precision equipment and sensitive measurements. However, a closely related and equally important challenge is noise reduction. Vibrations not only affect stability but can also generate significant noise, which can be detrimental in environments requiring quietness for […]

Introduction: Vibration isolation in standard settings is challenging enough, but when you move to extreme environments—be it the depths of the ocean, the vastness of space, or the harshness of arctic conditions—the complexity multiplies. These environments demand not only innovative solutions but also materials and designs that can withstand conditions far beyond the ordinary. This […]

Introduction: The field of vibration isolation is on the cusp of transformative changes, driven by groundbreaking research and innovative approaches. Emerging trends promise to redefine the effectiveness, scope, and application of vibration isolation technologies, making this an exciting time for industry professionals and researchers alike. This blog post ventures into the latest trends in vibration […]

Introduction: As environmental sustainability becomes a paramount concern across all sectors, the field of vibration isolation is no exception. Innovations in green materials and eco-friendly practices are setting new standards, reducing the environmental impact while maintaining, or even enhancing, the effectiveness of vibration isolation solutions. This blog explores the advancements and practices that underscore the […]

Introduction: In the intricate world of vibration isolation, adhering to industry regulations and standards is not just about compliance—it’s a cornerstone of innovation, safety, and quality. As industries evolve, so do the benchmarks for vibration isolation systems, affecting a wide array of sectors from manufacturing to biomedical research. This blog post delves into the significance […]

Introduction: The quest for precision and stability transcends industries, each faced with its unique set of challenges when it comes to managing vibrations. Customized vibration isolation solutions have become pivotal in addressing these diverse requirements, showcasing the adaptability and importance of tailored approaches. This post explores how specific industries leverage custom vibration isolation technologies to […]

Introduction: In an era where technology continually reshapes the boundaries of what’s possible, the fields of artificial intelligence (AI) and the Internet of Things (IoT) have begun to merge with vibration isolation practices. This integration heralds a new age of precision, efficiency, and predictive capabilities in managing vibrations across various applications. This blog explores how […]

Introduction: The final frontier presents unique challenges and demands unparalleled precision, particularly when it comes to isolating sensitive instruments and equipment from vibrations in space. This post delves into the sophisticated world of vibration isolation for space applications, from launch to orbit and beyond. The Unique Challenge of Space: Overview of the harsh vibrational environment […]

Introduction: In the quest for unparalleled precision and performance in industries ranging from aerospace to biotechnology, the role of advanced materials in vibration isolation cannot be overstated. This post explores the frontier of materials science, spotlighting the innovative materials redefining the effectiveness of vibration isolation systems. The Evolution of Materials in Vibration Isolation: Brief historical […]

Introduction: As we venture further into the future of vibration isolation, understanding its impact on the ground becomes crucial. Through a series of case studies, this blog post illuminates the transformative power of advanced vibration isolation technologies across various sectors. From enhancing precision in scientific research to ensuring manufacturing excellence, these real-world applications underscore the […]

After covering troubleshooting and optimization, the next logical step in the series would be to look forward into the future of vibration isolation technology. This blog post could explore emerging trends, innovative technologies, and how these advancements are set to revolutionize precision in various industries. This forward-looking perspective not only educates your audience about what […]

Introduction: After selecting and implementing a vibration isolation system suited to your specific needs, ensuring its continued optimal performance is paramount. Like any sophisticated equipment, vibration isolation systems may require adjustments, troubleshooting, and regular maintenance to perform at their best. This guide offers insights into common issues, effective troubleshooting strategies, and tips for optimizing your […]

Introduction: With an understanding of the critical role and fundamental mechanics of vibration isolation, the next step is navigating the landscape of solutions available. This guide is designed to help you, whether you’re outfitting a quality control lab, a manufacturing facility, or a research lab, make informed decisions on selecting the ideal vibration isolation system […]

For the next blog in the series, we’ll move from an introductory overview to a more detailed look at how vibration isolation technology works, focusing on the types of systems available and how they’re applied in real-world scenarios. This blog aims to bridge the gap between basic understanding and more advanced technical insights, appealing to […]

Certainly! Given your interest in selling vibration isolation products to this market, a blog series tailored to your audience could significantly help in educating and engaging potential customers. The blog can start with introductory information and gradually delve into more technical aspects. Let’s outline the first blog post focused on introducing vibration isolation, its importance, […]

Certainly! Here’s a list of professionals who commonly use the inspection machines mentioned earlier, along with their job titles, roles, and some of the challenges they often face in their work. Manufacturing Quality Control Quality Control Inspector Role: They inspect and test materials, parts, and products to ensure they meet predefined standards and specifications. This […]

Manufacturing Quality Control Coordinate Measuring Machine (CMM): Used for precise measurement of the geometry of physical objects by sensing discrete points on the surface with a probe. Optical Comparator (Profile Projector): Projects a magnified image of a part onto a screen for measurement and inspection purposes. Vision Inspection Systems: Automated machines that use cameras and […]

Inspection machines are crucial tools in both manufacturing quality control and research settings, including university labs and biomedical labs. Their applications span a wide range of tasks, from ensuring product quality to advancing scientific research. Here’s an overview of how inspection machines are used across these settings: Manufacturing Quality Control Dimensional Accuracy: Inspection machines like […]

Axometrics: high quality vibration decoupling for five-axis microscope systems Bilz BiAir® membrane air spring isolators integrated in an LCD Production Machine from Axometrics Axometrics Inc. USA Level reset accuracies > ± 0,01 mm

AVL: Trouble-free operation of engine test benches AVL engine test bench with Bilz BiAir® membrane air suspension system AVL List GmbH From test speed 500 1/min to 10,000 1/min Decoupling or insulation efficiency > 75-95%.

Boschert: rubber air springs for highly effective shock and vibration isolation Punching machine for sheet metal working tasks from Boschert – with FAEBI® rubber air springs from Bilz Boschert GmbH + Co KG Vibration isolation ratio > 90 %

Due to the declining availability of serial interfaces, the web interface of the AIS/EPPC system has been revised. During this revision, various adjustments/improvements have been made, a selection of the most important new features is briefly listed below: Logging function: A logging function has been added to monitor the system parameters and improve traceability in […]

Polytec: laboratory benches for laser vibrometers Illustration of a static application with Bilz BiAir® PAS pendulum air spring as the optimum isolator for Polytec laboratory benches. Polytec GmbH Horizontal natural frequency 1,2 Hz Level reset accuracy +/- 0,01 mm

Binnig and Rohrer Nanotechnology Center at IBM Research Laboratories: combined sound and vibration isolation for noise-free laboratories Binnig and Rohrer Nanotechnology Center at IBM Research Laboratories vibrations v Target value (Frequency range < 10 Hz): v < 1 μm/s vibrations v Measured values (result) (Frequency range < 10 Hz): v < 0,3 μm/s vibrations v […]

In the dynamic landscape of scientific research, where breakthroughs are often contingent upon the minutest of details, the significance of stable and ultra-low vibrations cannot be overstated.

As we’ve witnessed the evolution of machine leveling from manual shimming to sophisticated laser systems and automated adjustments, it’s clear that the field is not static. The future promises even more advancements, driven by emerging technologies and the ever-growing demand for precision, efficiency, and sustainability in manufacturing. This blog post explores the current trends shaping […]

In an era where businesses must navigate the complexities of global supply chains, environmental uncertainties, and ever-present risks of operational disruptions, resilience has become a key factor for success. Operational resilience refers to an organization’s ability to anticipate, prepare for, respond to, and recover from operational disruptions. Within the manufacturing sector, ensuring that machinery is […]

As industries march towards a future dominated by automation and smart technologies, the process of machine leveling is not left behind. Traditionally seen as a manual task requiring significant human expertise and intervention, machine leveling is on the cusp of transformation. Automation, powered by advancements in robotics, artificial intelligence (AI), and the Internet of Things […]

In the realm of high-precision manufacturing, where the tolerances are measured in micrometers and the quality of the final product can hinge on the minutest of details, machine leveling takes on an elevated significance. The challenges associated with achieving and maintaining optimal machine alignment in such environments are substantial, yet they must be meticulously addressed […]

Lean manufacturing principles aim to eliminate waste, enhance productivity, and achieve a seamless flow in production processes. Within this framework, every aspect of the manufacturing process is scrutinized for efficiency gains, including the foundational step of machine leveling. Proper machine leveling is not just a prerequisite for equipment operation; it’s a strategic lever for lean […]

In the complex ecosystem of manufacturing, precision and consistency are the cornerstones of quality control. Machine leveling, a fundamental yet sometimes overlooked process, plays a critical role in ensuring that production lines not only operate efficiently but also produce items that meet stringent quality standards. This blog post explores the synergy between machine leveling and […]

As manufacturing industries worldwide continue to navigate through the waves of globalization, technological advancements, and sustainability pressures, machine leveling technologies are not left untouched. The push towards more efficient, precise, and environmentally friendly manufacturing processes has led to significant shifts in how machine leveling is approached. This blog post explores the global trends influencing machine […]

As the manufacturing landscape evolves with technological advancements and the integration of smart factory principles, the demand for a highly skilled workforce capable of navigating these complex environments grows. Advanced machine leveling, a critical component of maintaining operational efficiency and product quality, stands as a testament to this shift. The transition from traditional leveling methods […]

As industries evolve in the face of technological advancements and changing market demands, the arena of machine leveling is no exception. This crucial process, foundational to the precision and efficiency of manufacturing operations, is ripe for innovation. Looking ahead, several key areas promise to redefine machine leveling, making it more accurate, efficient, and integrated with […]

In the pursuit of manufacturing excellence, efficiency and productivity stand as paramount goals for industrial operations. A key, yet often underestimated, factor in achieving these goals is the strategic importance of machine leveling. Proper machine leveling goes beyond merely setting up equipment; it lays the foundation for streamlined operations, high-quality output, and minimized downtime. This […]

The fourth industrial revolution, or Industry 4.0, is transforming manufacturing with digital technologies that merge the physical and digital worlds. This era brings unprecedented connectivity, automation, and data-driven decision-making to the forefront of industrial operations. Machine leveling, a fundamental aspect of setting up manufacturing and production equipment, is no exception to this transformation. This blog […]

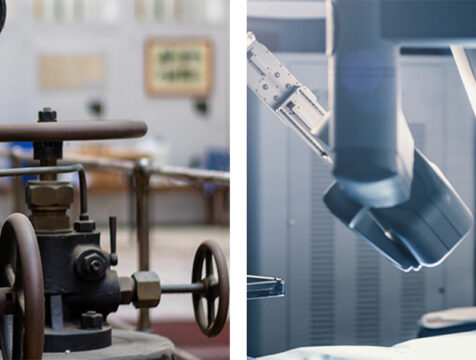

Machine leveling has long been a cornerstone of industrial setup, ensuring that machinery operates efficiently, accurately, and safely. However, the methods and tools used in machine leveling have evolved significantly over the years, moving from simple physical tools and techniques to advanced digital technologies and integrated systems. This blog post explores the journey of machine […]

In the world of manufacturing, the installation and leveling of machinery are critical steps that can significantly influence operational efficiency, product quality, and equipment lifespan. To provide deeper insights into the best practices and challenges of machine leveling, we’ve reached out to several industry professionals. Their experiences shed light on the nuances of installation across […]

The foundation of precision in manufacturing lies in how well machinery is installed and leveled. Different types of machinery, due to their unique operational characteristics and requirements, demand specific leveling techniques. This blog post explores the nuances in leveling techniques for various machines, such as CNC machines, presses, lathes, and injection molding machines, offering insights […]

In the quest for sustainable manufacturing, every aspect of the production process is scrutinized for efficiency improvements, including the often-overlooked practice of machine leveling. Precise machine leveling not only enhances the operational effectiveness and lifespan of machinery but also plays a crucial role in optimizing energy consumption. This blog post explores the impact of machine […]

Maintaining the precision and performance of industrial machinery is an ongoing task that extends well beyond the initial installation and leveling. Over time, environmental factors, operational stresses, and wear can lead to the need for re-leveling and maintenance. This blog post highlights the importance of periodic maintenance and the re-leveling process, offering guidance on how […]

Machine leveling is a critical step in the setup of manufacturing equipment, ensuring that machinery operates efficiently and accurately. However, even with careful planning and execution, issues can arise that may affect the precision and stability of your equipment. This blog post addresses common problems encountered during the machine leveling process and provides practical troubleshooting […]

The leveling of heavy machinery is not just a task of precision; it’s a significant safety concern. Ensuring that heavy equipment is properly leveled is critical for the safety of operators and the longevity of the machinery itself. This blog post will discuss the essential safety considerations and best practices to keep in mind when […]

Precision in machine leveling is not just about achieving operational efficiency; it’s about harnessing advanced techniques and technologies to ensure the utmost accuracy, stability, and performance of machinery. This blog post explores some of the cutting-edge methods and tools that have revolutionized the process of leveling heavy machinery, offering insights into how these advancements can […]

The precision and stability of your machinery directly influence your manufacturing process’s efficiency, safety, and product quality. Achieving this precision often hinges on the tools and equipment used during the machine leveling process. This blog post will explore the essential tools for effective machine leveling, offering insights into their selection and maintenance for optimal performance. […]

Machine leveling is more than just a step in the installation of heavy machinery; it’s a cornerstone of operational efficiency, product quality, and equipment longevity in manufacturing environments. This blog post delves into the myriad ways in which precise machine leveling impacts the manufacturing process, supported by industry insights and real-world examples. Ensuring Product Quality […]

Machine leveling is a critical step in setting up equipment that ensures operational efficiency, safety, and longevity. This guide is tailored for machines with a significant number of leveling wedges, such as Plastic Injection Molding Machines, Extruders, Die Cast Machines, and Large Machining Centers. By following this comprehensive procedure, you’ll ensure your machine is perfectly […]

Question: Dear Marc, In the realm of industrial machinery, downtime can be costly. Recently, we encountered a setback with a broken air spring on our machine. Given its German origin, we’re concerned about the lead time for a replacement. Can you shed light on this? Answer: In the fast-paced world of industrial machinery, downtime is […]

Question: Dear Marc, In the dynamic landscape of industrial machinery, every element contributes to the overall performance and efficiency. Today, let’s explore a critical aspect of machine enhancement: the integration of anti-vibration mounts onto an eccentric press lacking a dedicated anti-vibration system. Answer: Assessment of Total Weight and Dynamics Understanding the total weight and dynamic […]

Welcome to a fascinating journey into the realm of ultra-low temperature scanning tunneling microscopy and spectroscopy (STM/STS). In a groundbreaking case study conducted by Yande Que, Amit Kumar, Michael S. Lodge, and their esteemed colleagues from the Division of Physics and Applied Physics at Nanyang Technological University, Singapore, delve into the design and performance of […]

In the world of vibration isolation technology, the proper setup of an isolation table is crucial for optimal performance. In this guide, we’ll walk you through the step-by-step process of unboxing and assembling your vibration isolation table, ensuring you achieve the best results for your specific needs. Unpackaging Your Isolation Table Upon receiving your Bilz […]

In the ever-evolving landscape of manufacturing, precision has become essential. The Binnig Rohrer Ultra Low Vibration Lab, located in Zurich, is at the forefront of delivering unmatched precision in the production of microscopic components. This blog explores how this remarkable lab, in tandem with the Active Isolation System (AIS), revolutionizes manufacturing for critical applications.

The Problem with a Competitor’s Damaged Precision Leveling Wedge The competitor’s free-standing precision leveling wedge was initially a reliable solution for achieving precise machine leveling. However, over time, it suffered from extensive damage, accumulated dirt, and grease, compromising its effectiveness and performance. This case study aims to compare the shortcomings of the competitor’s product with […]

Flat panel displays have become a common part of our everyday lives. We interact with them at almost every turn, from sending an email on your computer, to watching your favorite show on TV or browsing social media on your smartphone. You’re even reading this on one now! With technology at the forefront of our […]

Steel springs are a thing of the past. Air spring isolators are the new and improved solution for isolating vibration, shock, or structure borne noise. They offer a variety of benefits over a traditional steel spring to help you achieve a greater isolation effect and keep your equipment running properly. Bilz offers two air spring […]

In an era of rapidly evolving technology, the semiconductor industry stands at the forefront of innovation. Semiconductors manage the flow of electricity through an intricate process of binding valence electrons from different atoms. Other elements are then introduced to the semiconductor, where electricity can flow throughout the circuit. These chips are responsible for operating most […]

Tired of imprecise and slippery machine installations in special environments? Want to ensure safe and fast work processes and precise results? We have a solution! Our new leveling wedges in stainless steel are machine feet designed for the finest leveling when installing machines, particularly under high loads. These leveling wedges are particularly suitable for applications […]

Case Study: Remote Troubleshooting of FAEBIⓇ Air Spring Installation In the ever-evolving world of testing and measurement, the stability of equipment is of paramount importance. The precision and reliability of results rely heavily on how effectively the testing machinery is isolated from external vibrations. At Bilz USA, we understand this necessity and provide top-notch vibration […]

Imagine if we could manipulate matter so small that it’s beyond what the naked eye can see, potentially changing industries like healthcare, energy, and electronics. This is what nanotechnology is all about—a fast-paced and exciting field that’s like a microscopic frontier of science. But working on such a small scale also brings unique challenges. One […]

Bilz USA: Your Anti-Vibration and Leveling Experts Bilz USA engineers anti-vibration and leveling solutions that meet your high standards and unique requirements. Designed and manufactured in Germany, our products are built to last and feature the latest vibration isolation technology. Demands continue to escalate for the operation of modern machinery. Our products allow you to […]

Bilz USA had an incredible week at the 2022 International Manufacturing Technology Show. From connecting with manufacturers to checking out the latest technology in the industry, we gained valuable insight that we would like to share with you. Keep reading to learn about all of the exciting things that happened while we were at IMTS […]

Plastic is one of the most used materials in the world. To keep up with the worldwide demand for plastic products, plastic processing plants need to be operating efficiently. From injection molding machines to granulators and mills, each piece of equipment is a vital part of the manufacturing process. These machines each complete different tasks, […]

Vibration Site Surveys: Preventing Issues Before They Arise When installing new machinery or facing ongoing vibration problems, conducting a vibration site survey is a game-changer. This service allows us to measure vibration levels in your lab or manufacturing plant, comparing them against the specifications of each machine. Our team evaluates whether the vibration levels are […]

Building or expanding a manufacturing plant can be an exciting process in a company’s growth. Often hand in hand with the construction or expansion of a plant comes new equipment installation or relocation of existing equipment in the plant which may require the installation of new machinery foundations that often require isolation from its surroundings […]

Each manufacturing environment can pose different challenges. When working in a lab setting it is crucial to overcome vibration and level challenges to ensure accuracy in your work or experiments. In this instance, a specially tailored solution is ideal. Bilz vibration isolated tables are constructed to cater to your specific needs. Let’s dive into the […]

Natural magnetic fields exist everywhere in the universe. They occur whenever an electric charge is in motion. The more electrical energy in motion, the greater the magnetic field produced. When low-frequency magnetic fields are present, emanating from electrical power cables, railways vehicles, or elevators, it can create functionality issues with sensitive pieces of equipment. It […]

We would like to welcome Bryan Toaz to the Bilz USA team! Read our Q&A with Bryan to learn about his role as an Application Engineer at Bilz, his background, and how his passion for engineering started! What is your role at Bilz? As an Application Engineer, I am here to help our customers solve […]

Highly-precise machines call for highly-precise leveling and vibration isolation solutions. Bilz air springs are an ideal vibration isolation solution for vibration-sensitive equipment, but in order for your air spring system to work properly it needs an effective level control system. Electronic Pneumatic Position Control is the ultimate system for highly-precise machines. Let’s explore how this […]

We would like to welcome Matt Brower to a new role at Bilz USA! Matt Brower is a Business Strategist with expertise in sales, marketing, branding, and leading a business. Over the past ten years, Matt has built Hey Now! Media, a marketing agency specializing in branding, websites, and digital marketing. Throughout his time at […]

Have you ever wondered how an air spring effectively isolates vibration and structure borne noise? Well, it is through a system called mechanical pneumatic level control. Bilz level control systems are significant components in the function of FAEBI® and FAEBI® – HD rubber or BiAir ® membrane air springs. Let’s dive into how exactly this […]

Optimizing Your Leveling Wedge It’s time to upgrade your leveling wedge! Choosing the right additions for your leveling wedge and application can help ensure that you are achieving optimum leveling of your equipment. Bilz offers a variety of threaded rods, isolation washers, mounts, anchors, and more that each come in different sizes and types, so […]

In the old days of manufacturing, you would have a quality room with all the measurement equipment. As goods were made, they would come off the line and have to be taken to the quality room in a separate area to determine if a part was in spec and good to go in order to […]

Bilz understands that your equipment is essential. We aim to help achieve proper leveling and vibration isolation as quickly as possible. As a distributor of Bilz Germany, we keep many products stocked and ready for when an order is placed. The way each product is assembled and shipped can differ and certain products require us […]

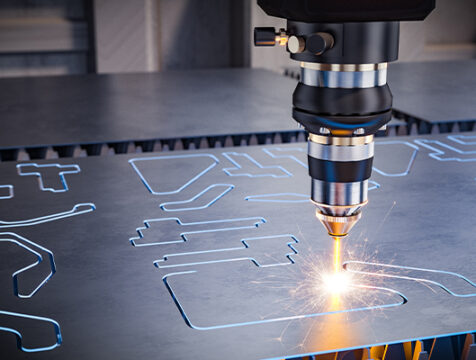

Drilling machines, lathes, presses, saws, and shearing machines. The list continues! Metal processing is a large industry with many different applications and pieces of equipment. Each machine plays an important role in the production process. This also means that each piece of equipment has its own vibration isolation and leveling needs. We’ve helped take the […]

Modern machines and equipment continue to progress, providing better performance and efficiency. While this increase in equipment capabilities is great for productivity, it also leads to an increased need to effectively isolate vibration in order to keep the machines working at their best. If you find your equipment isn’t working properly, vibration may be the […]

Having trouble passing calibration with your coordinate measuring machine? Your stamping press may be to blame. When your manufacturing environment has both stamping presses and coordinate measuring machines present it is important to consider how vibration may affect the capabilities of your equipment. Stamping presses produce vibration that can negatively impact the accuracy of your […]

The purpose of a stamping press is to reshape metal with a die. Dies are considered female or male, depending on the shape and use of the final product. A press is comprised of three main parts: a bolster plate, onto which the die is clamped; the ram/slide that acts like a hammer, and the […]

To what degree is anti-vibration control important? Given that there’s an entire branch of engineering devoted to eliminating its ill effects, we feel it’s safe to say “extremely.” Vibration engineers work to design machines with the goal of eliminating excess movement. Custom-made machines they devise may include internal monitors in the form of sensors or […]

It’s no secret that we are in an incredibly challenging and uncertain time. Along with fearing for our lives, many people are having to navigate uncharted waters in an uncertain business climate as well. The cases of COVID-19 are growing rapidly here in the US, and with it the need for additional medical supplies, on […]

Top 5 Considerations When Preparing for a New Machine When bringing a new machine into your plant or factory there are a couple things to consider and get in place prior to machine arrival to ensure a smoother installation.

Learn more: Fixing Vibration Issues Vibration isolation is the process of isolating an object, such as a piece of equipment, from the source of vibrations. Vibration is undesirable in many domains, primarily engineered systems and habitable spaces, and methods have been developed to prevent the transfer of vibration to such systems.

Today’s measuring machines operate with utter precision. Such accuracy has become achievable as production perfects itself through the rise of precision tools that lead to higher quality, greater safety, and longer performance. One resulting improvement we can all appreciate is increased auto life. Whereas with older models of production cars (from the 1960’s) rarely made […]

Learn more: Fixing Vibration Issues Vibration isolation is the process of isolating an object, such as a piece of equipment, from the source of vibrations. Vibration is undesirable in many domains, primarily engineered systems and habitable spaces, and methods have been developed to prevent the transfer of vibration to such systems.

Learn more: Fixing Vibration Issues Vibration isolation is the process of isolating an object, such as a piece of equipment, from the source of vibrations. Vibration is undesirable in many domains, primarily engineered systems and habitable spaces, and methods have been developed to prevent the transfer of vibration to such systems.

Learn more: Fixing Vibration Issues Vibration isolation is the process of isolating an object, such as a piece of equipment, from the source of vibrations. Vibration is undesirable in many domains, primarily engineered systems and habitable spaces, and methods have been developed to prevent the transfer of vibration to such systems.

Automotive test stands serve one particular purpose: to allow OEMs to gauge the performance and function of an engine or transmission. Test stands are typically constructed to allow for the replication of various real-world conditions by precisely controlling the speed and torque of the unit under test.

Plastic injection molding machines rely on the force of a ram or a plunger to shape heated plastic granules into the desired form, from a tiny tab on aseptic packaging to a 5 gallon paint can or more. Custom designed molds determine the ultimate shape of the plastic, with significant investment and care taken to […]

Learn more: Fixing Vibration Issues Vibration isolation is the process of isolating an object, such as a piece of equipment, from the source of vibrations. Vibration is undesirable in many domains, primarily engineered systems and habitable spaces, and methods have been developed to prevent the transfer of vibration to such systems.

Learn more: Fixing Vibration Issues Vibration isolation is the process of isolating an object, such as a piece of equipment, from the source of vibrations. Vibration is undesirable in many domains, primarily engineered systems and habitable spaces, and methods have been developed to prevent the transfer of vibration to such systems.

Learn more: Fixing Vibration Issues Vibration isolation is the process of isolating an object, such as a piece of equipment, from the source of vibrations. Vibration is undesirable in many domains, primarily engineered systems and habitable spaces, and methods have been developed to prevent the transfer of vibration to such systems.

Vibration Isolation There are two main kinds of vibration isolation: source/sender and receiver isolation. Source isolation is the vibration isolated mounting of a machine in order to reduce its pulse or sinusoidal vibration forces. This protects objects in the environment such as adjacent machines, the building and people from the disturbing forces. The special task […]

A machine suffering from vibration or leveling issues won’t function at 100% capacity, but what exactly are the signs or behaviors of an out of level machine? How can we identify misalignment problems quickly to prevent bigger issues, such as a potential shutdown, down the line?

Among the various types of anti-vibration support, air springs are one of the most popular, due to their versatility. As a pneumatic device, air springs can be used with or without a level control system. Generally, air springs are deployed when better isolation efficiency is needed. With the use of a level control system, air […]

Modernization seeps into every industry, sector, and generation! When it comes to machine modernization specifically, technological advances can have you wondering what level of overhaul and replacement is actually necessary to keep up with the times but still drive high ROI. Additionally, equipment doesn’t last forever. Normal wear and tear requires ongoing attention, as machines […]

How do you determine that vibration is the problem? You know you have a problem. Every time you run a specific part, the product is out of spec. One of the reasons this happens is due to vibration. This handy list will help you either rule out or rule in favor of vibration as the […]

So, you bought a new-to-you die casting machine for your business. Now what? Can you start operations immediately, or do you need to spend time leveling a refurbished die casting machine.? That’s a good question, and the short answer is definitely yes! But if you’re wondering why leveling is necessary before you get things up […]

So, you bought a new-to-you die casting machine for your business. Now what? Can you start operations immediately, or do you need to spend time leveling a refurbished die casting machine? That’s a good question, and the short answer is definitely yes! But if you’re wondering why leveling is necessary before you get things up […]

What’s a cleanroom? A cleanroom is designed to allow manufacturers to control particulate contamination, temperature, humidity, and other potential variables, consequently protecting the product or manufacturing process from air or human borne contaminants.

Diagnosing machines in your shop can be difficult, time consuming, and potentially expensive. That’s why it’s best to be prepared by educating yourself as much as possible before the problem arises so you know if you need to level your machine. Do you know what to look for if a product is running out of […]

Leveling can play a huge role in avoiding downtime, maintaining product quality and consistency, increasing capacity, and lowering operating costs. Machines, especially large machines performing heavy duty jobs, have to contend with shock and vibration that can leave your end product out of spec. Here are some machine leveling best practices to help your equipment stay […]

So, you bought a new, used, or refurbished plastic injection molding machine for your business. Now what? Can you start operations immediately, or does it need leveled?

Wondering how to fix vibration issues in your machine? The bad news is there is no way to completely eliminate vibration – it will always be there. But the good news is that based on your needs you can control how much vibration there is and how much it affects your end product. This concept […]

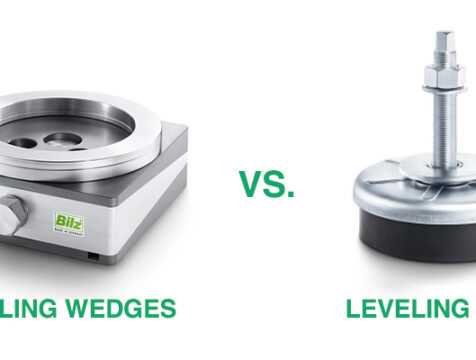

Leveling wedges vs. leveling feet is an age-old question we’re often asked by customers. From the isolation of a single press with isolation pads to active vibration isolation of highly sensitive equipment in the semiconductor industry, there is virtually no technical vibration problem that can’t be solved. So when your machine needs isolation efficiency, which […]

Wondering how to fix vibration issues in your machine? The bad news is there is no way to completely eliminate vibration – it will always be there. But the good news is that based on your needs you can control how much vibration there is and how much it affects your end product. This concept […]

Vibration Diagnostics Checklist: How do you determine vibration is the problem? You know you have a problem when every time you run a specific part, the product is out of spec. One of the reasons this happens could be due to vibration. This handy vibration diagnostics checklist will help you either rule out or rule […]

So, you bought a new, used, or refurbished plastic injection molding machine for your business. Now what? Can you start operations immediately, or does it need leveled? That’s a good question, and the short answer is definitely yes! But if you’re wondering why you need to spend time leveling before you get things up and […]

Leveling can play a huge role in avoiding downtime, maintaining product quality and consistency, increasing capacity, and lowering operating costs. Machines, especially large machines performing heavy duty jobs, have to contend with shock and vibration that can leave your end product out of spec. Here are some machine leveling best practices to help your equipment stay […]

Cheap leveling equipment takes longer to install, is less accurate, is an overall cheaply made product, and doesn’t last as long. But is that always a bad thing? Read on to learn a bit more about the different kinds of leveling options and what types of situations require different quality products. What makes some leveling […]

Vibration Technology, vibration isolation or insulation, vibration damping – whatever you want to call it, Bilz is your expert in this field. In order to ensure your personal background knowledge, we have compiled and explained some of the central terms and definitions around this topic.

Vibration Technology, vibration isolation or insulation, vibration damping – whatever you want to call it, Bilz is your expert in this field. In order to ensure your personal background knowledge, we have compiled and explained some of the central terms and definitions around this topic. Vibration or oscillation Vibrations are temporal changes of state variables (e.g. […]

Machine Data Engine Dynamometer on Stolle cast iron bed-plate Products Used Qty (4) BiAir 2-ED Air Springs Qty (1) MPN-PVM-KS Level Control System Project Goals Absorb vibration energy created when engine is run up and loaded by the Dyno Engine Dyno Stolle Cast Iron Bed Plate with BiAir Air Springs

What’s a cleanroom? A cleanroom is designed to allow manufacturers to control particulate contamination, temperature, humidity, and other potential variables, consequently protecting the product or manufacturing process from air or human borne contaminants. What are the sources and causes of contamination in a cleanroom? Depending on the product or manufacturing process, there is a […]

Proper installation can help reduce downtime, increase capacity and lower operating costs. There can be a lot of variance depending on the machine, but there are some basic best practices that when employed correctly can help ensure your machines are properly installed and working FOR you for a long time to come.

Machine Data Engine Dynamometer on Stolle cast iron bed-plate Products Used Qty (4) BiAir 2-ED Air Springs Qty (1) MPN-PVM-KS Level Control System Project Goals Absorb vibration energy created when engine is run up and loaded by the Dyno Engine Dyno Stolle Cast Iron Bed Plate with BiAir Air Springs

AIS Platform – Active vibration Isolation System for Platform

Machine Data

Paramed Medical Systems MRI

Weight of MRI: 10,450 pounds

Max Patient Weight: 350 pounds

Platform Weight: 500 pounds

Total Isolated Weight: 11,300 pounds

AIS Platform – Active vibration Isolation System for Platform

Machine Data

Wafer Mask Inspection Tool installed on a raised floor in a Clean Room AIS – Active vibration Isolation Platform for Clean Room.