So, you bought a new, used, or refurbished plastic injection molding machine for your business. Now what? Can you start operations immediately, or does it need leveled?

That’s a good question, and the short answer is definitely yes! But if you’re wondering why you need to spend time leveling before you get things up and running, we can explain. Let’s start with the basics.

Was your machine leveled when it was installed? A huge frame can seem strong enough to keep a machine aligned. Maybe you’re asking yourself if it’s even possible for it to have drifted out of level.

No matter the state of your machine – new, used, or refurbished – plastic injection molding is a precise process. In order to maintain consistent, high quality part output, your machine needs to be level.

On a micro level, what this really means is that the two halves of the mold have to fit perfectly and evenly to keep the plate parallel and prevent flash, damage to the mold, and parting-line wear.

If it’s way out of level you may have problems initially. However, the machine has guides inside that can help mask these issues for a period of time.

But overtime, the guides will actually start to wear and create problems not just for the machine, but for the finished die, mold, and the product. This cascade of issues can wreak general havoc on your machine and cause you to have to replace molds as well. Replacing them can be a major expense.

You may start seeing flash, issues with dimensions being out of tolerance, and even defects. If you have flash, you need a secondary operation to clean up the flash (lip), but burns and dimensional defects aren’t so easily remedied and could even mean that you would need to scrap the parts.

A lesser known issue, comes in the form of diagnosis. When part problems occur, often times the assumption is an issue with the mold itself. Processors can waste valuable time and money repairing the mold and running the press to identify the problem, when it is an issue with leveling instead.

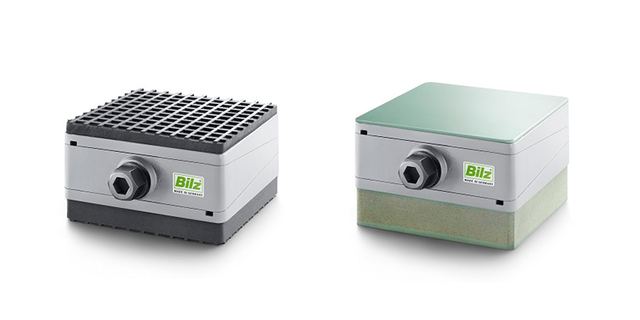

Leveling creates better quality parts and longer die life. Save yourself the headache and level up your new-to-you machine. Anytime you are replacing a machine it’s a good idea to spend a minimal cost to put new feet on or upgrade to a wedge. Leveling wedges are easier to install, provide better performance, and last longer than leveling feet or shims.

Bilz USA is the leading industry expert in vibration isolation and leveling technology. Our experts can answer your questions and show you the best leveling and vibration options for your new-to-you machine. Click here to get in touch.