Learn more: Fixing Vibration Issues Vibration isolation is the process of isolating an object, such as a piece of equipment, from the source of vibrations. Vibration is undesirable in many domains, primarily engineered systems and habitable spaces, and methods have been developed to prevent the transfer of vibration to such systems.

Today’s measuring machines operate with utter precision. Such accuracy has become achievable as production perfects itself through the rise of precision tools that lead to higher quality, greater safety, and longer performance. One resulting improvement we can all appreciate is increased auto life. Whereas with older models of production cars (from the 1960’s) rarely made […]

Learn more: Fixing Vibration Issues Vibration isolation is the process of isolating an object, such as a piece of equipment, from the source of vibrations. Vibration is undesirable in many domains, primarily engineered systems and habitable spaces, and methods have been developed to prevent the transfer of vibration to such systems.

Learn more: Fixing Vibration Issues Vibration isolation is the process of isolating an object, such as a piece of equipment, from the source of vibrations. Vibration is undesirable in many domains, primarily engineered systems and habitable spaces, and methods have been developed to prevent the transfer of vibration to such systems.

Learn more: Fixing Vibration Issues Vibration isolation is the process of isolating an object, such as a piece of equipment, from the source of vibrations. Vibration is undesirable in many domains, primarily engineered systems and habitable spaces, and methods have been developed to prevent the transfer of vibration to such systems.

Automotive test stands serve one particular purpose: to allow OEMs to gauge the performance and function of an engine or transmission. Test stands are typically constructed to allow for the replication of various real-world conditions by precisely controlling the speed and torque of the unit under test.

Plastic injection molding machines rely on the force of a ram or a plunger to shape heated plastic granules into the desired form, from a tiny tab on aseptic packaging to a 5 gallon paint can or more. Custom designed molds determine the ultimate shape of the plastic, with significant investment and care taken to […]

Learn more: Fixing Vibration Issues Vibration isolation is the process of isolating an object, such as a piece of equipment, from the source of vibrations. Vibration is undesirable in many domains, primarily engineered systems and habitable spaces, and methods have been developed to prevent the transfer of vibration to such systems.

Learn more: Fixing Vibration Issues Vibration isolation is the process of isolating an object, such as a piece of equipment, from the source of vibrations. Vibration is undesirable in many domains, primarily engineered systems and habitable spaces, and methods have been developed to prevent the transfer of vibration to such systems.

Learn more: Fixing Vibration Issues Vibration isolation is the process of isolating an object, such as a piece of equipment, from the source of vibrations. Vibration is undesirable in many domains, primarily engineered systems and habitable spaces, and methods have been developed to prevent the transfer of vibration to such systems.

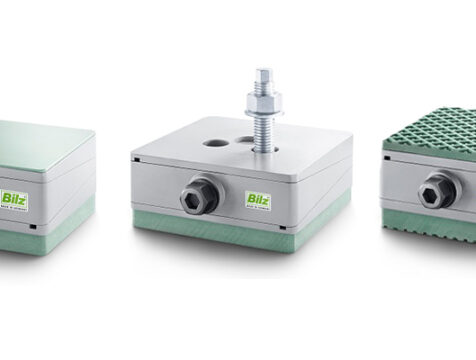

Vibration Isolation There are two main kinds of vibration isolation: source/sender and receiver isolation. Source isolation is the vibration isolated mounting of a machine in order to reduce its pulse or sinusoidal vibration forces. This protects objects in the environment such as adjacent machines, the building and people from the disturbing forces. The special task […]

A machine suffering from vibration or leveling issues won’t function at 100% capacity, but what exactly are the signs or behaviors of an out of level machine? How can we identify misalignment problems quickly to prevent bigger issues, such as a potential shutdown, down the line?

Among the various types of anti-vibration support, air springs are one of the most popular, due to their versatility. As a pneumatic device, air springs can be used with or without a level control system. Generally, air springs are deployed when better isolation efficiency is needed. With the use of a level control system, air […]

Modernization seeps into every industry, sector, and generation! When it comes to machine modernization specifically, technological advances can have you wondering what level of overhaul and replacement is actually necessary to keep up with the times but still drive high ROI. Additionally, equipment doesn’t last forever. Normal wear and tear requires ongoing attention, as machines […]

How do you determine that vibration is the problem? You know you have a problem. Every time you run a specific part, the product is out of spec. One of the reasons this happens is due to vibration. This handy list will help you either rule out or rule in favor of vibration as the […]