Need help selecting the right Products?

Extremely heavy-duty isolation pad with the highest level of constancy. For very heavy and longbed machines.

Isolation pad with high level consistency, specifically for machines with low intrinsic rigidity such as processing centres, lathes and grinding machines, etc.

Universally applicable insulation pad variant for machine tools, plastic and printing machines. Very well suited for machines that tend to “wander”.

Insulation pad for machines having high machine dynamics and only a small contact surface, e.g. presses, punches, shears etc.

Profiled insulation pad to compensate for uneven floors. Designed specifically for machines with only a small contact surface and high dynamics, e.g. presses, punches, shears etc.

Soft insulation pad without profile with excellent insulation effect, designed specifically for machines with low dynamics such as medium presses, punches etc.

By multiple layering of 2–6 Bilz isolation pads to form pad sets, reduced natural frequencies can be achieved and thus the isolating effect can be significantly increased compared to single-layer isolation pads.These pad sets are ideal for large machines and swing foundations.Even after years of dynamic stress, the vibration-damping and isolation properties of the isolation pad sets remain unchanged.

Very soft insulation pad with profile and very high insulation effect. Suitable for machines with low dynamics.

Soft insulation pad without profile, designed specifically for effective insulation when installed on upper floors.

Very soft insulation pad for static applications providing optimum insulation through low frequency matching, such as for measuring and inspection machines, scales, microscopes.

Insulation pad for the highest insulation values, can be stacked up to 6 times, perfectly suitable as a pad set for foundation insulation.

Bilz anti-slip pads and distance pads, for mechanical levelling and anti-slip. Not to be used for vibration isolation.

Electronic-pneumatic level control system for use in dynamic and vibration-sensitive measuring machines as well as testing and production machines.

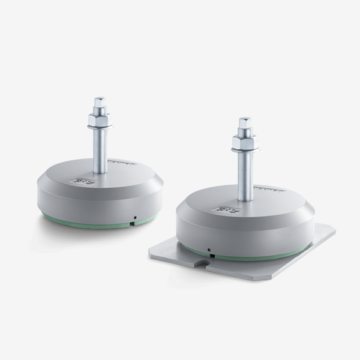

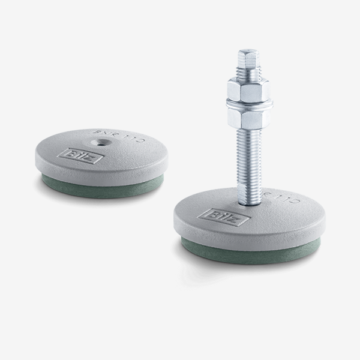

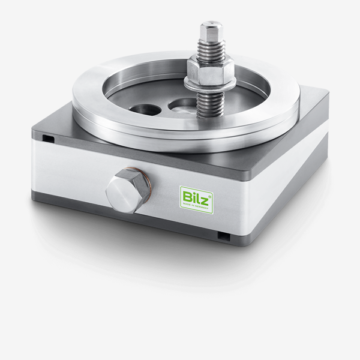

Round leveling element, specifically for high demands on horizontal stability, e.g. injection moulding machines, presses, punches.

BNSH: without bolt-on floor mounting

BNSHA: with bolt-on floor mounting

Suitable bolts and nuts with standard thread can be supplied on request.

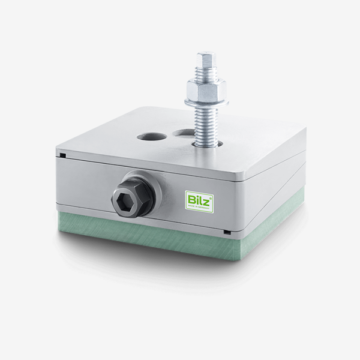

Square leveling element with compensation of angular differences by means of movable leveling bolt.

BNV: optionally with movable leveling bolt

BNVS: connected with movable leveling bolt

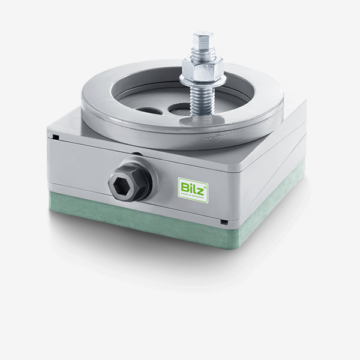

Round leveling element with compensation of angular differences by means of movable leveling bolt.

BNR: optionally with movable leveling bolt

BNRS: connected with movable leveling bolt

Round, stainless steel leveling element with compensation of angular differences by means of movable leveling bolt. Specially designed for applications in the food, pharmaceutical and clean room industries.

BNRV: optionally with movable leveling bolt

BNRSV: connected with movable leveling bolt

Cost-effective round, stainless steel leveling element with compensation of angular differences by means of movable leveling bolt. Specially designed for applications in the food, pharmaceutical and clean room industries.

BFE: round, stainless steel version, with flexible leveling bolt

Cost-effective rubber-metal element, designed specifically for robust vibration and structure-borne noise isolation of machines and aggregates in outdoor areas.

GMA: Bolt-on rubber-metal parts

Cost-effective leveling element for machines with high vertical and horizontal dynamic forces.

BNL: Steel, with leveling bolt

A large range of different bolts are available for each type of leveling element.

Free-standing precision leveling wedges especially for machines without mounting holes in the machine bed.

Our accessories for precision leveling wedges.

Bolt-on precision leveling wedges for machines with strong forces that require a firm connection to the machine bed.

Used for machines that need to be anchored to the floor due to unfavourable centre of gravity conditions and low inherent rigidity.

Can be bolted to the machine bed (PKAK) / bolt-through (PKDK) with calotte and used to compensate

for angle differences, especially for machines with high geometric requirements.

Easily adjustable leveling wedge with excellent wear properties, particularly suitable for EMC and clean room applications, can be bolted to the machine bed (PKA-AL) or anchored to the floor (PKD-AL).

Easily adjustable leveling wedge with excellent wear properties, particularly suitable for EMC and clean room applications, can be bolted to the machine bed (PKAK-AL) or anchored to the floor (PKDK-AL), and to balance out angular differences

Bilz horizontal elements are used for machines with extremely strong horizontal forces or when machines are linked and have to be fixed laterally.

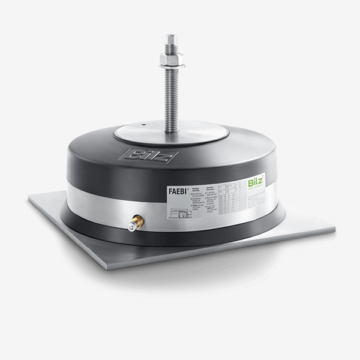

FAEBI® rubber air spring insulator.

Rubber air spring insulator FAEBI® in stainless steel.

FAEBI®-HD series with adjustable damping.

Extra high air cushioning due to two-chamber system. For reducing the amplitudes of movement in highly dynamic systems, also in the resonance range, thus reducing machine wear and improving production quality.

Low-frequency (vertical from 2.5 Hz) membrane air spring with precisely adjustable damping for effective vibration isolation.

Made from anodised aluminium to meet high demands on material properties.

Variants with lug for mounting valves (MPN) or displacement sensors are available with hose connections on the left (NL) or right (NR) on request.

Low-frequency (vertical 2.5 Hz) membrane air spring with precisely adjustable damping for effective vibration isolation.

Made from cast aluminium, universally applicable.

Very low-frequency (vertical 1.7 Hz) membrane air spring with precisely adjustable damping for effective vibration isolation.

Made from cast aluminium, universally applicable.

Very low-frequency (vertical 1.2 Hz) membrane air spring with precisely adjustable damping for effective vibration isolation.

Made from cast aluminium, universally applicable.

Air Springs Accessories

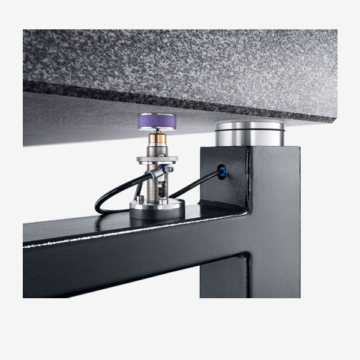

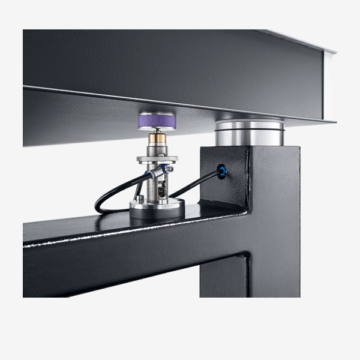

Reset accuracy is ± 1/10 mm

The reset accuracy is ± 1/100mm

Mechanical Level Control Systems accessories.

EPPC™ real-time level control achieves an optimum production accuracy of +/- 10 µm and a significant reduction of the deflection and settling times in response to dynamic load changes Intelligent browser-based user interface for setting, diagnostics and monitoring.

Active electronic-pneumatic vibration isolation with 3 or 6 degrees of freedom.

The modular system operates without disturbing heat generation, magnetic field fluctuations or high power consumption.

Mobile and autonomous, passive table platform, no compressed air and power supply necessary.

Mobile, passive table platform with convenient level adjustment, requires no power supply.

Mobile, passive table platform with mechanical-pneumatic level control and high isolation efficiency. No power supply necessary.

With level-controlled BiAir®-ED membrane air springs, vertical natural frequency 2.5 – 3 Hz, horizontal 2.8 – 3.5 Hz

With level-controlled BiAir®-OC membrane air springs, vertical natural frequency approx. 2 Hz, horizontal 2.8 – 3.5 Hz

With level-controlled BiAir®-PAS membrane air springs, vertical natural frequency approx. 2 Hz, horizontal approx. 1.2 Hz

With level-controlled BiAir®-ED membrane air springs, vertical natural frequency 2.5 – 3 Hz, horizontal 2.8 – 3.5 Hz

With level-controlled BiAir®-OC membrane air springs, vertical natural frequency approx. 2 Hz, horizontal 2.8 – 3.5 Hz

With level-controlled BiAir®-PAS membrane air springs, vertical natural frequency approx. 2 Hz, horizontal approx. 1.2 Hz

Qualified for all types of applications

Range of Applications:

Range of Applications:

Range of Applications:

Range of Applications:

Range of Applications: