Binnig and Rohrer Nanotechnology Center at IBM Research Laboratories: combined sound and vibration isolation for noise-free laboratories

The promotion of nanoscience is pursued at the Binnig and Rohrer Nanotechnology Center at IBM in Zürich. The smallest structures in the field of nanometers are examined here in order to generate materials for information and semiconductor technology. It is obvious that exceptional demands are placed on these research laboratories.

The six noise-free laboratories of the nanotechnology centre are situated eight meters underground. Here the most sensitive and most demanding research experiments on the nanoscale can be conducted. Before this, all interference variables relevant to nanotechnology such as vibrations, electromagnetic fields, temperature, humidity and sound had to be equally considered and, if possible, eliminated. These objectives required a new laboratory concept.

We were part of the team of the noise-free Labs of IBM Research during the planning phase already. Our competent technical advice was crucial for the project. After successful tests, we developed the solution for the underground laboratories: isolation against ground vibrations and isolation against sound.

We develop the solution for acoustics and ground vibrations from one source.

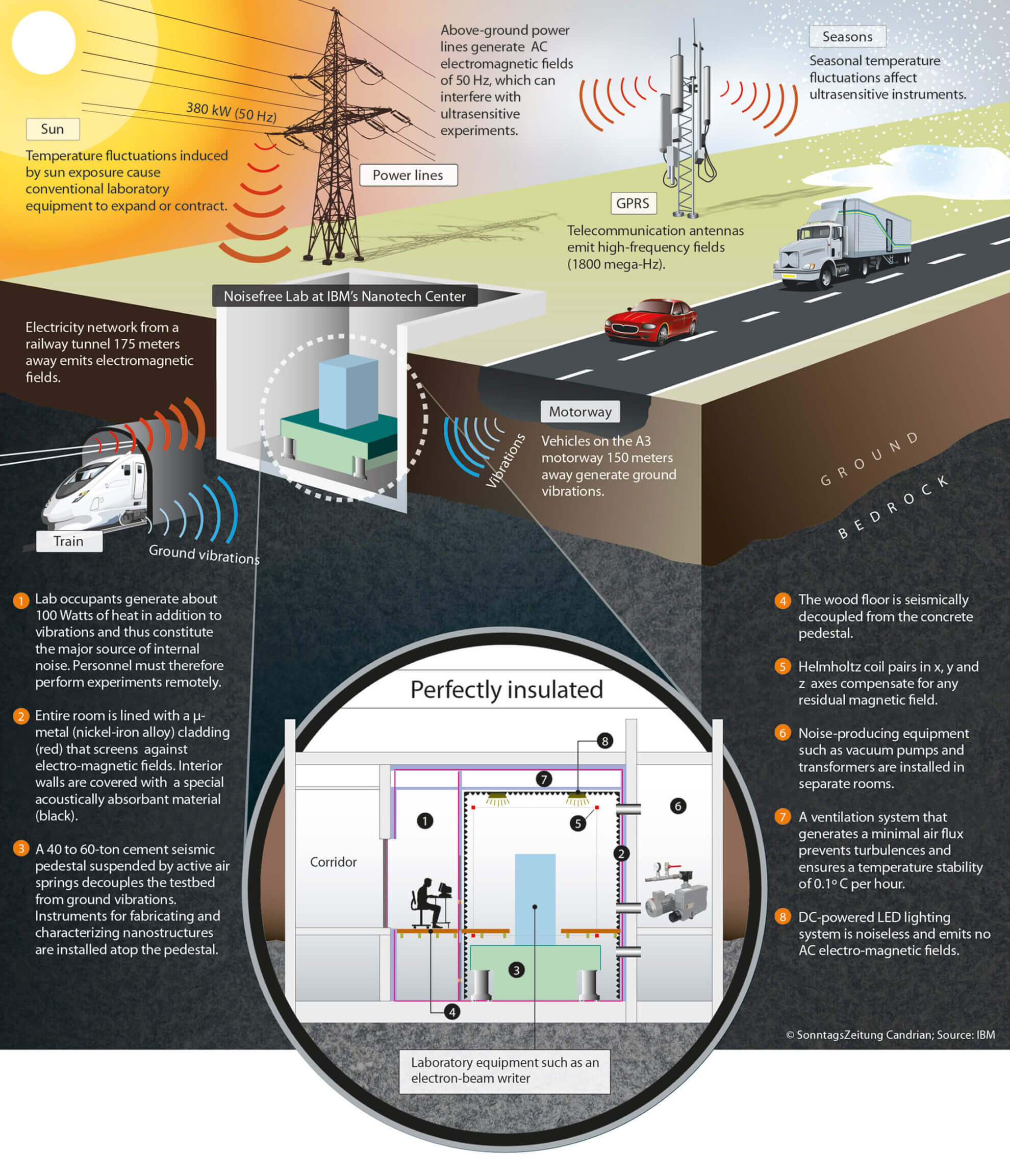

The illustration shows some of the most important measures for reducing external interference in the “Noise-free Labs” of the Binnig and Rohrer Nanotechnology Center of IBM and ETH Zurich.

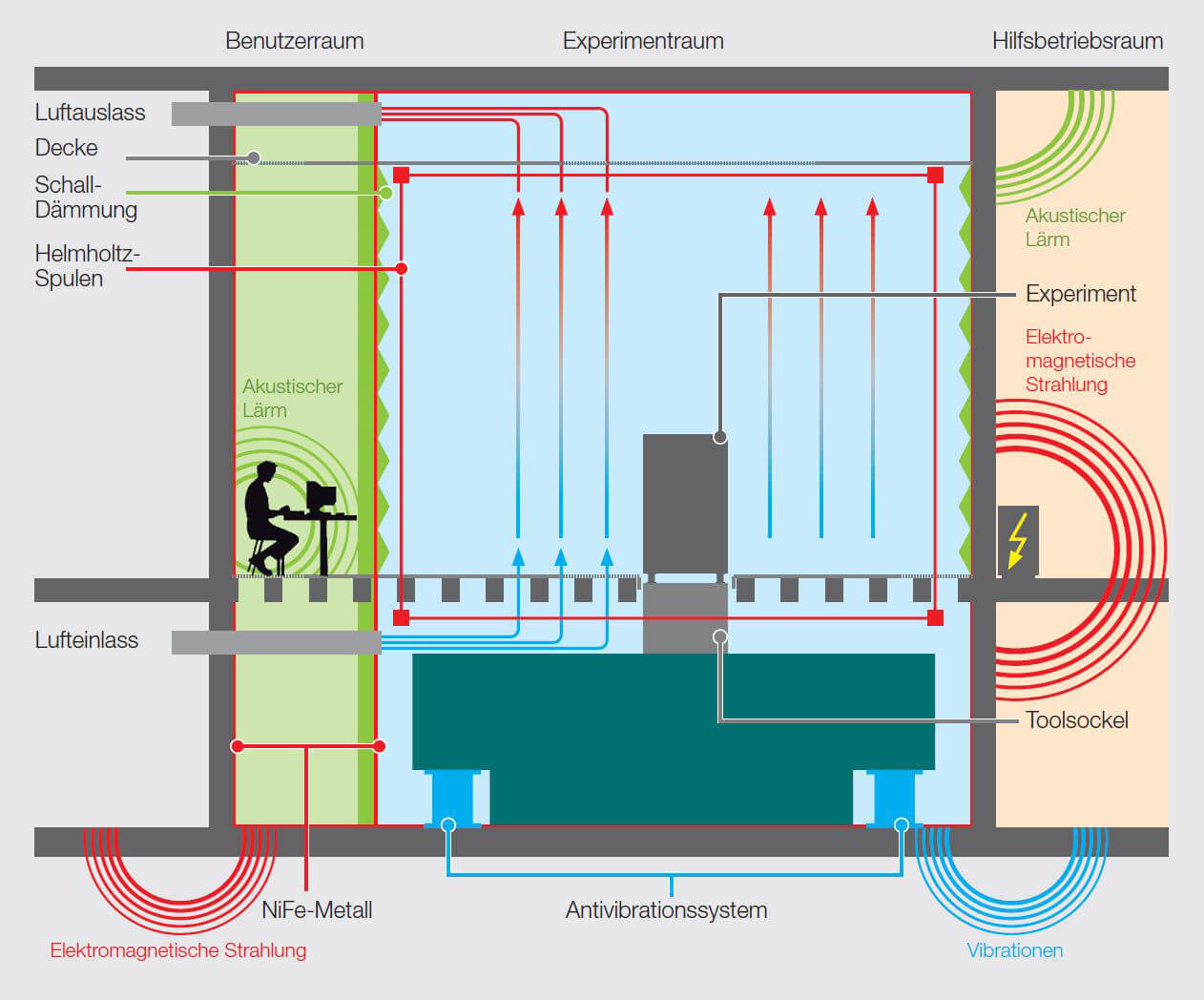

The sketch shows the result of perfect insulation with Bilz solutions for vibration insulation in the Binnig and Rohrer Nanotechnology Centers of IBM and ETH Zurich.

The planning objective for the six noise-free laboratories was that spatial laboratory conditions must only deteriorate minimally. This is because the various technical devices in an experiment are often major disruptive factors: mechanical pumps for vacuum generation or warmth development for example, and electro-magnetic radiation from mains and control equipment. With traditional experiments it is sufficient to block off individual parameters such as temperature for example. With metrological developments in nanotechnology, however, there are experiments which are sensitive to multiple or all five disturbance variables. Therefore, temperature, humidity, vibrations, sound and electromagnetic fields should all be blocked off at the same time. These challenges could only be mastered by looking at the overall system.

At the beginning of the project phase different highly sensitive experiments were evaluated and measuring and fabrication devices taken into consideration. These highly sensitive instruments, for example electron beam recorders, transmission electron microscopes and spin-polarised scanning tunnelling microscopes had to be mounted vibration free.

CAD drawing of insulation with Bilz AIS™ Active Isolation System for Binnig and Rohrer Nanotechnology Center of IBM and ETH Zurich

An air cushioned concrete block with the biggest possible mass was installed in each laboratory. The natural resonance of the air cushions is within the range of 1,2 – 2,4 Hz. The isolators are actively regulated through the air cushions. The experiments stand on these 34- to 80-tonne pedestals: the user, on the other hand, moves on a vibration decoupled floor.

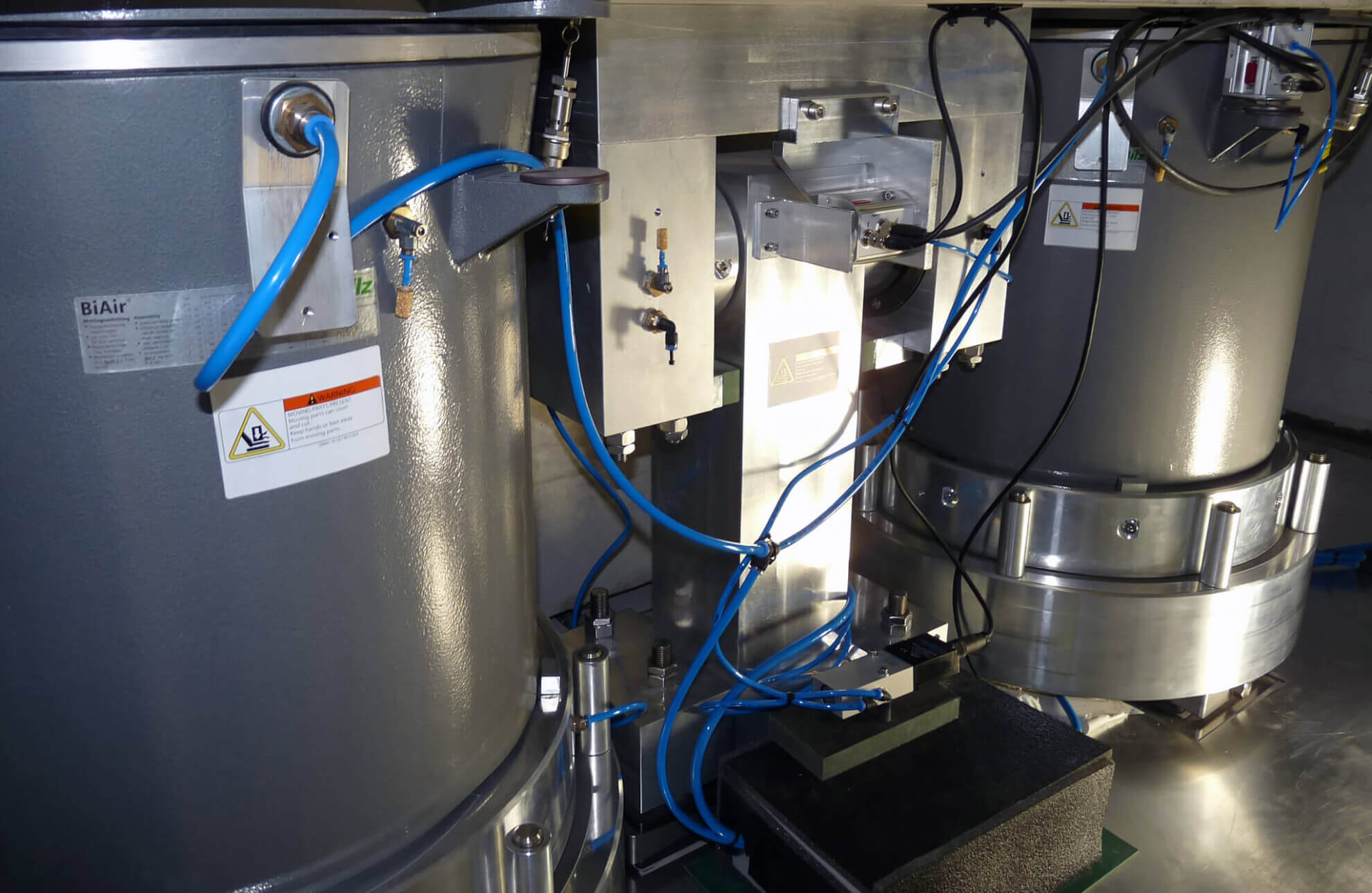

For this a new Bilz product was used here, the AIS™ Active Isolation System High Performance, our active electronic-pneumatic vibration isolation for the highest demands for isolation effectiveness, decay time and level constancy.

Underneath the laboratories trains drive past at high speed. The experiments are so well shielded, that this has no effect on the measurements.

The smallest structures in the area of nanotechnology, such as molecules and atoms, are researched in the noise-free laboratories. Even the conditions of a clean room environment would be too “noisy” for this type of work.

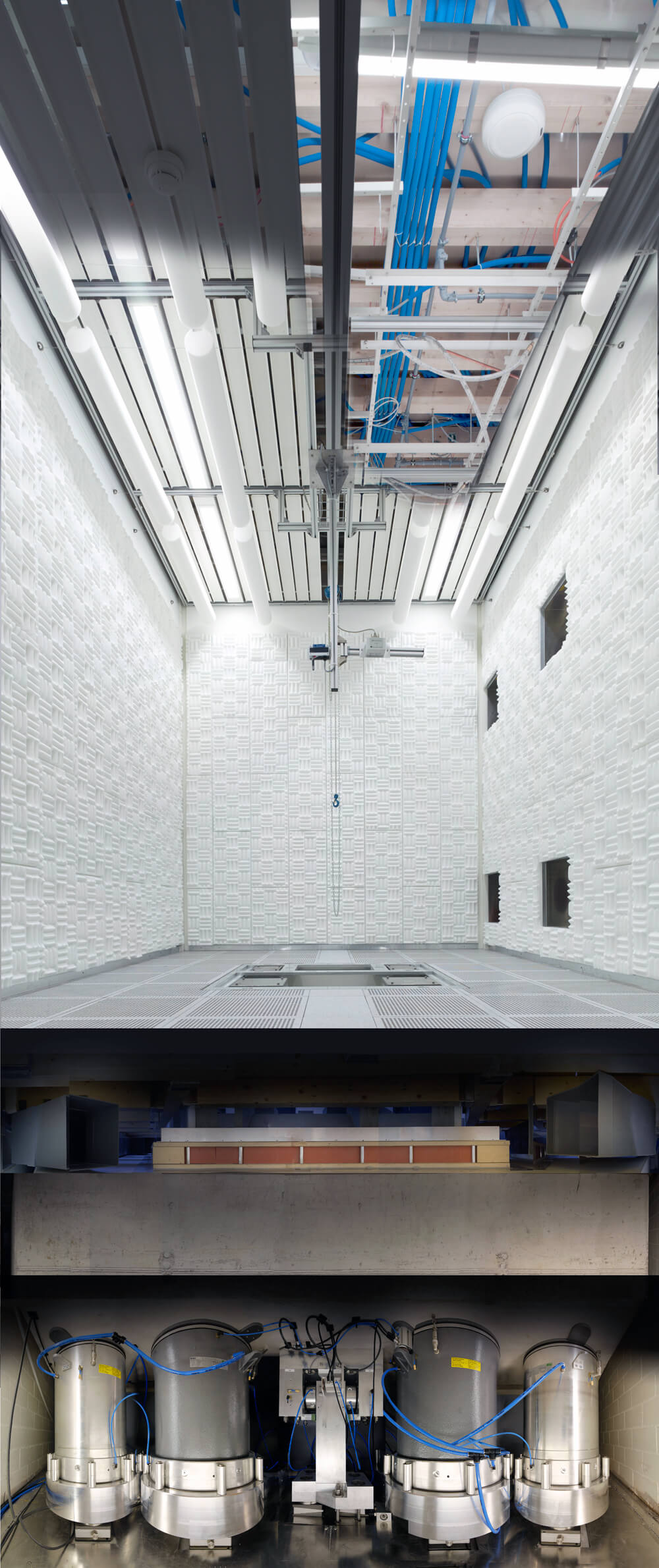

Installation of Bilz acoustic insulation material in the Binnig and Rohrer Nanotechnology Center experiment room (IBM Research Zurich)

Cross-section illustration of the insulations with Bilz vibration insulation for Binnig and Rohrer Nanotechnology Center of IBM and ETH Zurich.

Bilz acoustic elements, made of nap foam, enable optimised room acoustics and airborne sound insulation here. Our solutions for the absorption of sound energy are characterised by maximum sound damping or sound insulation and minimisation of the occurring sound pressure levels as well as the resulting reverberation times. The result is an extremely silent environment with drastically reduced disturbance.

Dipl.-Wirt.-Ing. Ulf Motz

Project Manager Bilz Vibration Technology AG