Need help selecting the right Isolation Pads?

Extremely heavy-duty isolation pad with the highest level of constancy. For very heavy and longbed machines.

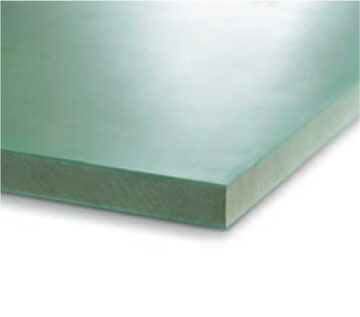

Isolation pad with high level consistency, specifically for machines with low intrinsic rigidity such as processing centres, lathes and grinding machines, etc.

Universally applicable insulation pad variant for machine tools, plastic and printing machines. Very well suited for machines that tend to “wander”.

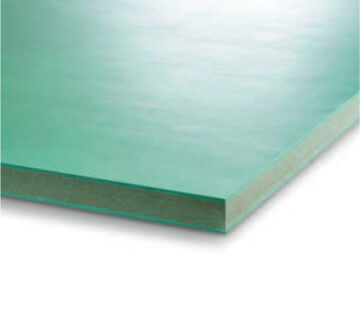

Insulation pad for machines having high machine dynamics and only a small contact surface, e.g. presses, punches, shears etc.

Profiled insulation pad to compensate for uneven floors. Designed specifically for machines with only a small contact surface and high dynamics, e.g. presses, punches, shears etc.

Soft insulation pad without profile with excellent insulation effect, designed specifically for machines with low dynamics such as medium presses, punches etc.

By multiple layering of 2–6 Bilz isolation pads to form pad sets, reduced natural frequencies can be achieved and thus the isolating effect can be significantly increased compared to single-layer isolation pads.These pad sets are ideal for large machines and swing foundations.Even after years of dynamic stress, the vibration-damping and isolation properties of the isolation pad sets remain unchanged.

Very soft insulation pad with profile and very high insulation effect. Suitable for machines with low dynamics.

Soft insulation pad without profile, designed specifically for effective insulation when installed on upper floors.

Very soft insulation pad for static applications providing optimum insulation through low frequency matching, such as for measuring and inspection machines, scales, microscopes.

Insulation pad for the highest insulation values, can be stacked up to 6 times, perfectly suitable as a pad set for foundation insulation.

Bilz anti-slip pads and distance pads, for mechanical levelling and anti-slip. Not to be used for vibration isolation.