Have you ever wondered how an air spring effectively isolates vibration and structure borne noise? Well, it is through a system called mechanical pneumatic level control. Bilz level control systems are significant components in the function of FAEBI® and FAEBI® – HD rubber or BiAir ® membrane air springs. Let’s dive into how exactly this system works!

Mechanical pneumatic level control not only prevents any unwanted deflections of the isolators, but also any out-of-level condition of the machine that can be caused by load changes on an air spring mounted machine or system. By rapidly adding or venting air, the air pressure within the air spring is matched to the respective load to automatically control the height of the individual air springs. This enables the highest degree of stability and effective isolation even with changes in the center of gravity.

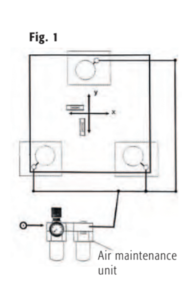

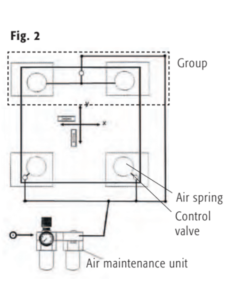

This system controls at least three air springs (See Figure 1 Below). If you need more than three isolators due to the design or load, it is important to still set up the system in three controlled groups to ensure proper function. This can be achieved by using multiple isolators in parallel as a group (See Figure 2 Below). In both instances, an additional air maintenance unit is installed upstream of the control valves to prepare the compressed air.

The level of the air spring is continuously monitored by a plunger. The plunger is directly applied to the slide valve and the air spring is either pressurized or vented. The height and level of the machine is adjusted using three valves and the target level is adjusted by turning the knurled adjustment ring.

The air maintenance units set the optimum system pressure and prepare the compressed air for the air spring system. The integrated compressed air preparation system traps incidental condensate and cleans the compressed air of particles such as rust and dust prior to entering the air spring system.

We offer a specially matched plunger isolation pad to reduce the vibrations and disturbances transmitted through the valve plunger. The plunger isolation pad is an additional isolation disc that is inserted between the valve plunger and the machine to reduce disturbances that would otherwise be transmitted through the valve plunger. This is ideal for sensitive machinery, particularly where the load is low.

Finger pinch protection is an additional safety component that reduces the risk of pinching a finger in the area of the valve or plunger. The finger pinch protection can be placed on the hard metal disc and can therefore be retrofitted to existing systems. For maintenance purposes, the finger pinch protection can be removed without damage for maintenance work.