Highly-precise machines call for highly-precise leveling and vibration isolation solutions. Bilz air springs are an ideal vibration isolation solution for vibration-sensitive equipment, but in order for your air spring system to work properly it needs an effective level control system. Electronic Pneumatic Position Control is the ultimate system for highly-precise machines. Let’s explore how this system works and why it is the ideal solution for vibration-sensitive machines!

Electronic Pneumatic Position Control, or EPPC™ is a robust and effective technology that can be paired with Bilz standard air springs. It offers real-time level control with up to six degrees of freedom. For each degree of freedom, there is one high-performance sero valve and one position sensor. The sero valve technology combined with high-resolution system processing allow for noiseless system control. Unlike electro-magnetic actuators, this system does not create disturbing heat generation, magnetic field fluctuations, or high power consumption.

This system is designed with efficiency in mind. It provides optimum positional accuracy and allows you to individually adjust the system’s parameters, such as damping. In addition, it has an optimized connecting system using CAN bus technology and an intelligent browser-based user interface. This interface hosts the system’s settings, diagnostics, and monitoring, making remote maintenance possible.

Electronic Pneumatic Position Control significantly reduces deflection and settling times in response to dynamic load changes. This makes this system best suited for high-precision machines, vibration-sensitive and highly dynamic measuring machines, microscopes, and test and production machines in the semiconductor industry.

EPPC™ can be combined with three or six air spring control groups. Bilz offers a wide range of air springs for system design. The high-performance electronics and pneumatic valves are mounted directly on the respective air springs. This allows virtually noise-free control without losses due to a pressure drop in the hose connection. The use of CAN bus technology ensures the simplest electrical cabling, making it possible to install the control unit up to 20 meters away.

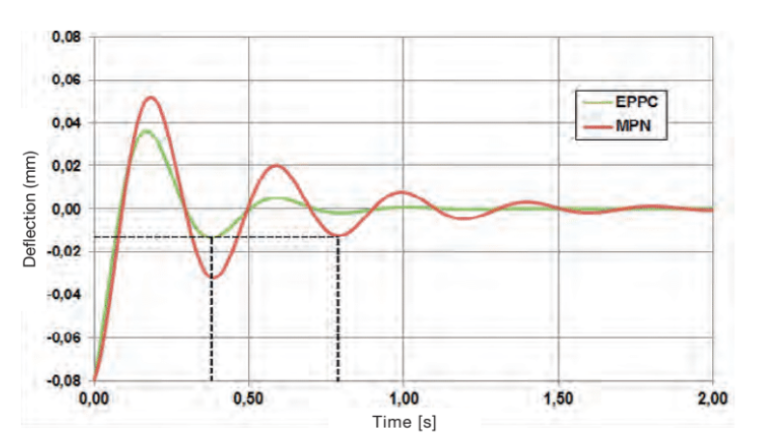

In comparison to a conventional mechanical pneumatic level control, EPPC™ has a significantly reduced settling time. At a deflection of -80 µm, the mechanical pneumatic level control system reaches a stable position after 0.75 seconds. With Electronic Pneumatic Position Control, the deflection time is reduced by 45% to 0.4 seconds. This is displayed in the figure below: