General PRODUCT DESCRIPTION

Our accessories complete the performance requirements of our air springs and consequently support an ideal vibration isolation.

Our accessories complete the performance requirements of our air springs and consequently support an ideal vibration isolation.

The FAEBI® rubber air springs are attached to the existing holes in the machine using the bolts provided (incl. one nut and one washer each). Anchoring to the floor is usually not necessary. A large range of different bolts are available for each variant. We are always happy to offer our advice.

| FAEBIⓇ | Item no . | Thread | Material | Length mm | |

|---|---|---|---|---|---|

| FAEBI® 50 | 19-0311 | M10 | Zinc plated steel | 100 | Request A Quote |

| FAEBIⓇ 75/100 | 19-0322 | M12 | Zinc plated steel | 100 | Request A Quote |

| FAEBIⓇ 125/150/200 | 19-0324 | M16 | Zinc plated steel | 125 | Request A Quote |

| FAEBI® 300/430 | 19-0327 | M20 | Zinc plated steel | 150 | Request A Quote |

| FAEBI® 580 | 19-0329 | M24 | Zinc plated steel | 150 | Request A Quote |

| FAEBIⓇ Stainless steel VA | Item no . | Thread | Material | Length mm | |

|---|---|---|---|---|---|

| FAEBI® 50 VA | 18-0005 | M10 | Stainless steel | 100 | Request A Quote |

| FAEBIⓇ 75/100 VA | 18-0016 | M12 | Stainless steel | 100 | Request A Quote |

| FAEBIⓇ 125/150/200 VA | 18-0066 | M16 | Stainless steel | 125 | Request A Quote |

| FAEBIⓇ 300/430 VA | 18-0044 | M20 | Stainless steel | 150 | Request A Quote |

| FAEBIⓇ 580 VA | 18-0052 | M24 | Stainless steel | 150 | Request A Quote |

| FAEBIⓇ - HD | Item no . | Thread | Material | Length mm | |

|---|---|---|---|---|---|

| FAEBI® 200 - HD | 19-0324 | M16 | Zinc plated steel | 125 | Request A Quote |

| FAEBI® 300 - HD / 430 - HD | 19-0327 | M20 | Zinc plated steel | 150 | Request A Quote |

| FAEBI® 580 - HD | 19-0329 | M24 | Zinc plated steel | 150 | Request A Quote |

Suitable for all rubber air springs. Applications with a constant centre of gravity during the production/testing process (no moving machine components, workpieces, etc., steady masses).

Difficult to access systems, where the manual checking of air pressure in the air springs is impeded.

The Bilz pressure control is the ideal addition to applications that do not need automatic level control. Instead of filling the air springs manually, they are connected to a constant compressed air supply. The working height of the individual isolators can each be individually set with one pressure regulator.

Advantages of FAEBI® pressure control

Simple and precise setting of the required pressure for each air spring or control group.

Suitable for all rubber air springs.

Item no. 40–0128

Hand pump for manual air filling.

Suitable for all rubber air springs.

Item no. 40–0128

Hand pump for manual air filling.

Compressed air gun with pressure gauge for air filling via existing compressed air supply.

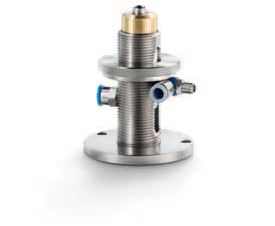

MPN-LCV for FAEBI® and FAEBI®-HD Rubber air spring isolators:

Item no. 61–0103 Standard version of the LCV with stainless steel washer MPN-LCV for BiAir® membrane air springs:

Item no. 61–0012 Standard version LCV with stainless steel washer MPN-LCV-short-Pad-A for BiAir® membrane air springs:

Item no. 61–0054 Shortened version of the LCV with plunger isolation pad.

MPN-LCV

The mechanical-pneumatic level control MPN-LCV with our robust LCV proportional valves is a simple but effective solution to prevent tilting as a result of load changes.

The target level is adjusted by turning the knurled adjustment ring and is maintained with an accuracy of ± 1/10mm.

Suitable for all membrane air springs.

ELECTRONIC-PNEUMATIC POSITION CONTROL EPPC™

EPPC™ real-time level control for efficient vibration isolation of vibration sensitive, highly dynamic machines and strict requirements on positional accuracy and setting time.

Further details regarding the BiAir® membrane air springs with electronic-pneumatic level control can be found in the chapter EPPC™ on pages 52–53.

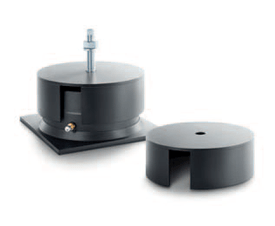

Material: Steel sheet (primed black)

For Faebi® and Faebi®-HD

If the surface of the FAEBI® elements is not completely covered by the bottom edge of the machine or the installation surface, an appropriate cover is required to ensure sufficient load distribution across the air spring. A hood will also provide protection from external damage.

For outdoor use, the hood is additionally equipped with a protective sleeve that protects against UV radiation and splash water.

Material: Stainless steel

For FAEBI® In stainless steel

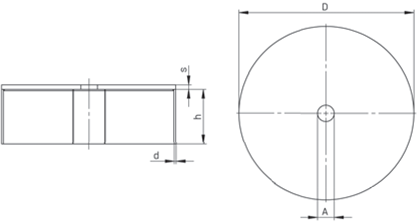

| Туре | Item no . | A mm | D mm | s mm | hmm | d mm | |

|---|---|---|---|---|---|---|---|

| AH - FAEBI® 50/75 | 40-0013 | 13 | 115 | 55 | 40 | 2 | Request A Quote |

| AH - FAEBIⓇ 100 | 40-0001 | 14 | 140 | 5 | 45 | 2 | Request A Quote |

| AH - FAEBIⓇ 125 | 40-0003 | ∞ 18 | 160 | LO 5 | 60 | 2 | Request A Quote |

| AH - FAEBIⓇ 150 | 40-0006 | ∞ 18 | 190 | LO 5 | 60 | 2 | Request A Quote |

| AH - FAEBI® 200 | 40-0007 | ∞ 18 | 255 | 5 | 60 | 3 | Request A Quote |

| AH - FAEBI® 300 | 40-0009 | 22 | 360 | 5 | 60 | 3 | Request A Quote |

| AH - FAEBIⓇ 430 | 40-0012 | 22 | 500 | 10 | 60 | 4 | Request A Quote |

| AH - FAEBI® 580 | 40-0014 | 27 | 680 | 10 | 60 | 4 | Request A Quote |

| Type | Item no. | Application | A mm | D mm | s mm | h mm | d mm | |

|---|---|---|---|---|---|---|---|---|

| AH - Stainless steel FAEBIⓇ 50/75 | 40–0163 | Indoor | 13 | 115 | 5 | 40 | 2 | |

| AH - Stainless steel FAEBI® 100 | 40–0002 | Indoor | 14 | 140 | 5 | 45 | 2 | Request A Quote |

| AH - Stainless steel FAEBIⓇ 125 | 40–0004 | Indoor | 18 | 160 | 5 | 60 | 2 | Request A Quote |

| AH - Stainless steel FAEBIⓇ 150 | 40–0005 | Indoor | 18 | 190 | 5 | 60 | 2 | Request A Quote |

| AH - Stainless steel FAEBIⓇ 200 | 40–0008 | Indoor | 18 | 255 | 5 | 60 | 3 | Request A Quote |

| AH - Stainless steel FAEBI® 300 | 40–0010 | Indoor | 22 | 360 | 5 | 60 | 3 | Request A Quote |

with protective sleeve

| Type | Item no. | Application | A mm | D mm | s mm | h mm | d mm | |

|---|---|---|---|---|---|---|---|---|

| AH - Stainless steel FAEBIⓇ 50/75 | 77-0016 | Outdoor | 13 | 115 | 5 | 40 | 2 | |

| AH - Stainless steel FAEBI® 100 | 77-0017 | Outdoor | 14 | 140 | 5 | 45 | 2 | Request A Quote |

| AH - Stainless steel FAEBIⓇ 125 | 77-0018 | Outdoor | 18 | 160 | 5 | 60 | 2 | Request A Quote |

| AH - Stainless steel FAEBIⓇ 150 | 77-0019 | Outdoor | 18 | 190 | 5 | 60 | 2 | Request A Quote |

| AH - Stainless steel FAEBIⓇ 200 | 77-0020 | Outdoor | 18 | 255 | 5 | 60 | 3 | Request A Quote |

| AH - Stainless steel FAEBI® 300 | 77-0021 | Outdoor | 22 | 360 | 5 | 60 | 3 | Request A Quote |

Looking for the right product?