General PRODUCT DESCRIPTION

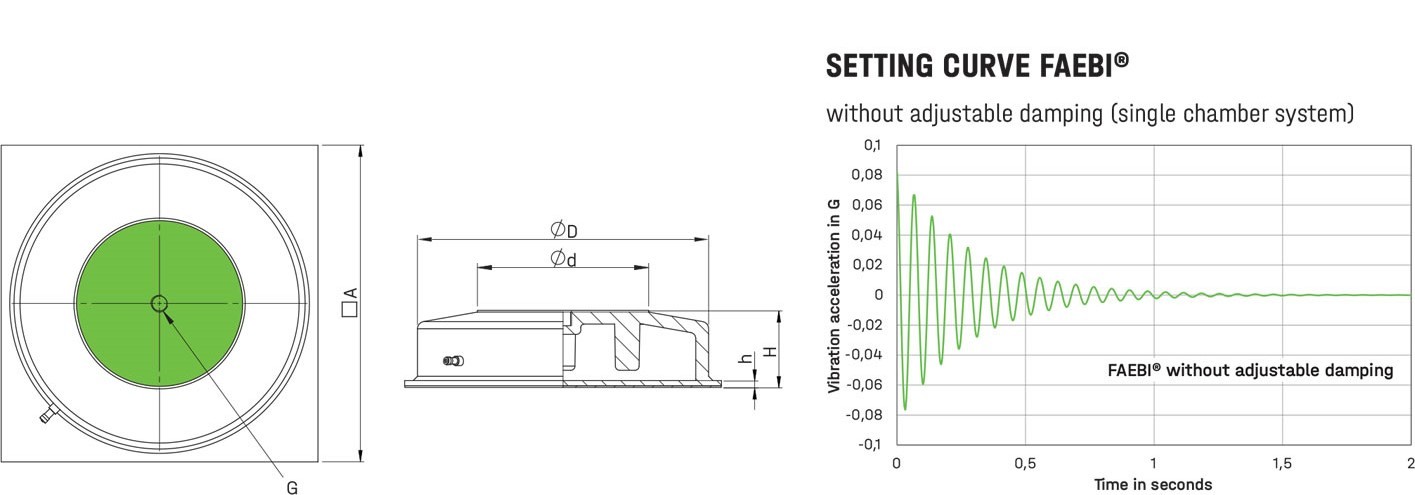

FAEBI® elements in the VA version were specifically developed for outside applications. Effortless vibration isolation of systems

in the open air such as air conditioning units, compressors, heat exchangers, cold water chillers.

Advantages over steel springs

Compared to steel springs, the use of air springs offers numerous advantages in vibration isolation:

- Flexible design of the isolation system: If the static or dynamic load changes, the deflection can be adjusted accordingly by adjusting the air pressure. This can be done either manually

or automatically (e.g. by Bilz level control). - Can be used in outdoor areas in combination with a stainless steel protective hood.

- Integrated damping, therefore separate isolation is not necessary.

- No transmission of structure-borne noise.

- Permissible temperature range: -20 °C to +60 °C.