General PRODUCT DESCRIPTION

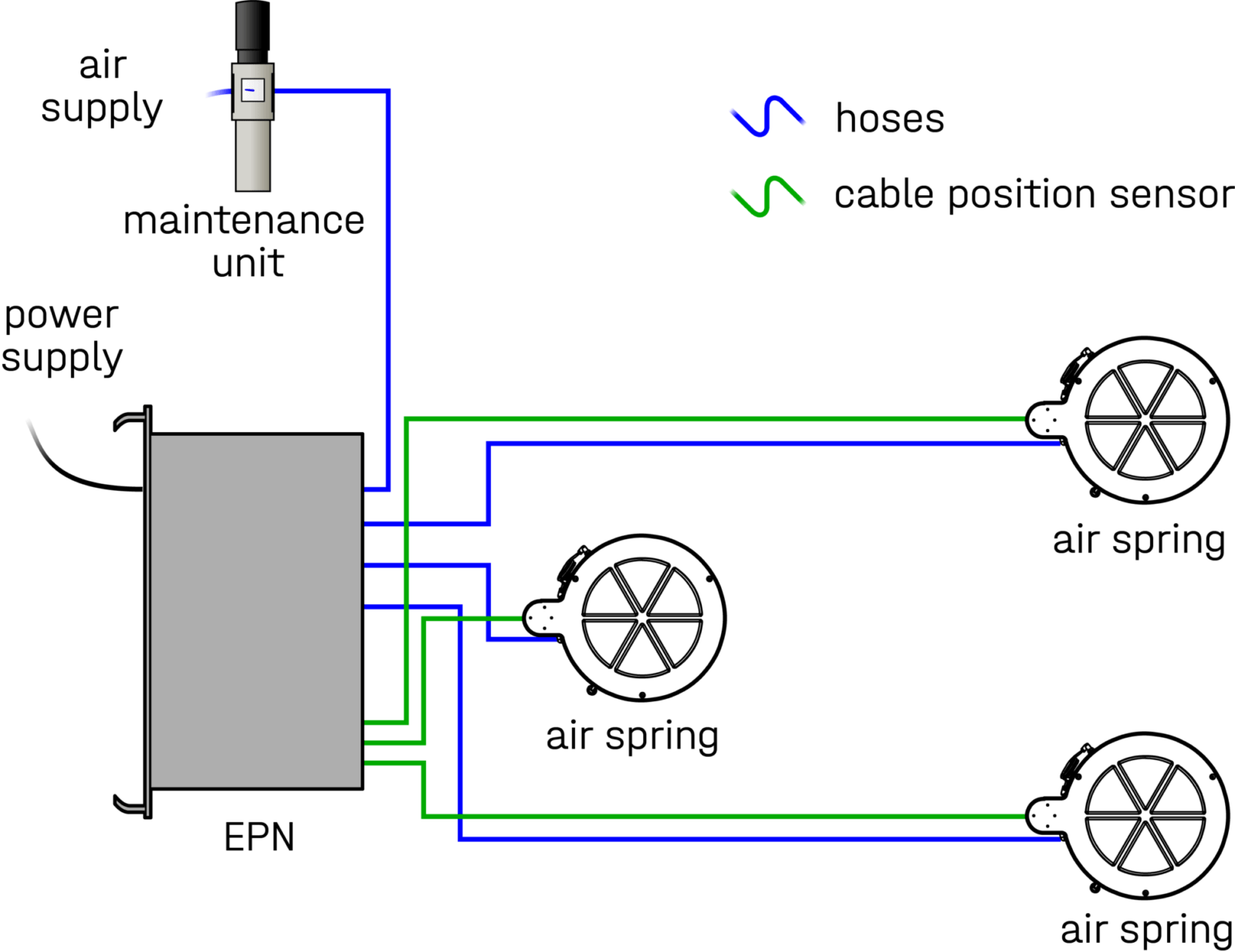

Electronic-pneumatic level control systems EPN are suitable for combination with BiAir® membrane air springs. By using

an intelligent control algorithm and electronic valves with flow rates of up to 250 l/min, significantly reduced deflections and decay times can be achieved compared to mechanical-pneumatic level control systems. The electronic-pneumatic level control systems from Bilz are therefore ideally suited for use in dynamic and vibration-sensitive measuring machines as well as testing and production machines.