In the ever-evolving landscape of manufacturing, precision has become essential. The Binnig Rohrer Ultra Low Vibration Lab, located in Zurich, is at the forefront of delivering unmatched precision in the production of microscopic components. This blog explores how this remarkable lab, in tandem with the Active Isolation System (AIS), revolutionizes manufacturing for critical applications.

The Binnig Rohrer Facility

Named after the two men who invented the Scanning Tunneling Microscope (STM) around 40 years ago, the Binnig Rohrer Ultra Low Vibration Lab is a cutting-edge facility in Zurich dedicated to nanotechnology research and manufacturing. Its state-of-the-art equipment and expertise enable precision manufacturing on a microscopic scale.

Challenges in Critical Applications

In critical environments like aerospace, precision is not a luxury—it’s a necessity. The slightest variations in temperature or vibrations can have disastrous consequences. Manufacturing components for these applications demands the utmost precision.

Addressing Interference

Unwanted noise and interference pose significant challenges in manufacturing critical components. Temperature fluctuations and vibrations can compromise component integrity, leading to potential failures. Eliminating noise and interference is crucial when working with components designed for demanding applications.

Introducing the Active Isolation System (AIS)

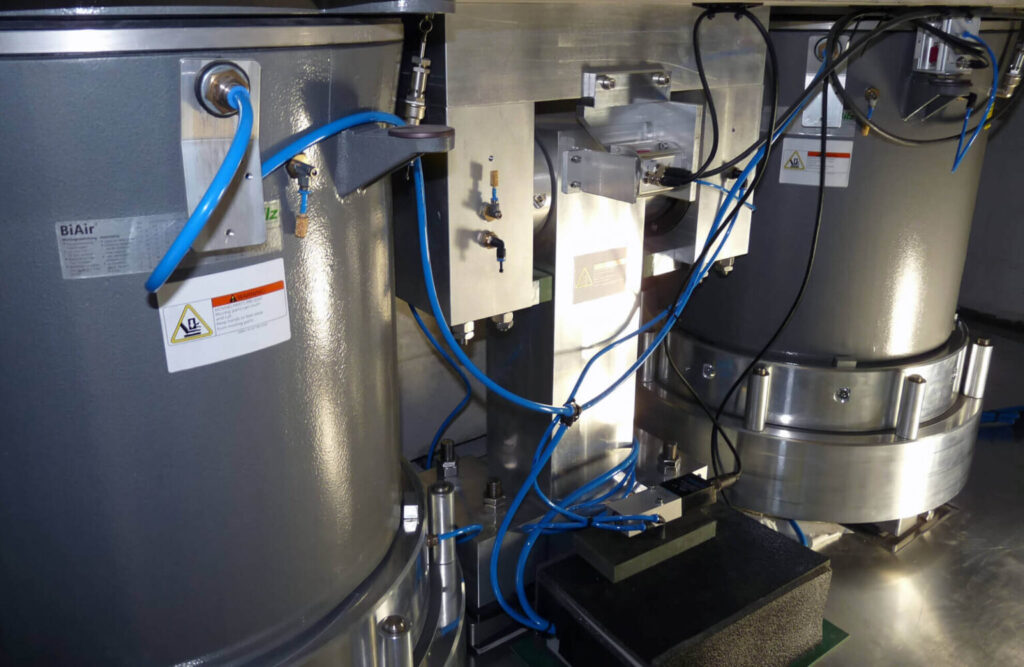

To overcome such challenges, the AIS offers an innovative solution. It incorporates a Bilz AIS system, consisting of massive air spring suspended and actively controlled concrete seismic blocks weighing 30-68 tons each. This advanced system creates an environment shielded from external influences. It is meticulously calibrated to detect and neutralize frequencies that could disrupt the manufacturing process.

Maintaining a Controlled Environment

Precision manufacturing requires a controlled and noise-free environment. The AIS effectively suppresses vibrations and disturbances, providing an ideal setting for the Binnig Rohrer facility to operate with exceptional accuracy.

The Importance of Calibration

Calibration plays a vital role in ensuring optimal performance. The AIS precisely addresses frequencies that could impact manufacturing processes, optimizing results for specific measurements and criteria.

The Binnig Rohrer Ultra Low Vibration Lab: Enabling Precision Manufacturing

The Binnig Rohrer Ultra Low Vibration Lab, in collaboration with the AIS, is a game-changer in precision manufacturing. By leveraging this advanced facility and integrating it with the AIS Bilz system, manufacturers can achieve unparalleled precision and overcome challenges in critical applications. These technologies drive the industry towards a new era of excellence, empowering the delivery of precise and reliable solutions for demanding environments.